5

The input reduction is primarily achieved by reducing the size of

the main burner orifices. To do this, the main burner orifices

require replacement with orifices sized for the particular installation

elevation. Correct orifice sizing and parts may be obtained from

the manufacturer. See the REPLACEMENT PARTS section of

this manual. When ordering, be sure to state the model number

and the altitude of the location where the heater is being

installed.

Upon completion of derating of the heater, adjustment to the gas

pressure regulator may be required. See ADJUSTMENT

PROCEDURE in this manual for inlet and manifold pressure

requirements.

Also, due to the input rating reduction required at high altitudes,

the output rating of the appliance is also reduced and should be

compensated for in the sizing of the equipment for applications.

FEATURES

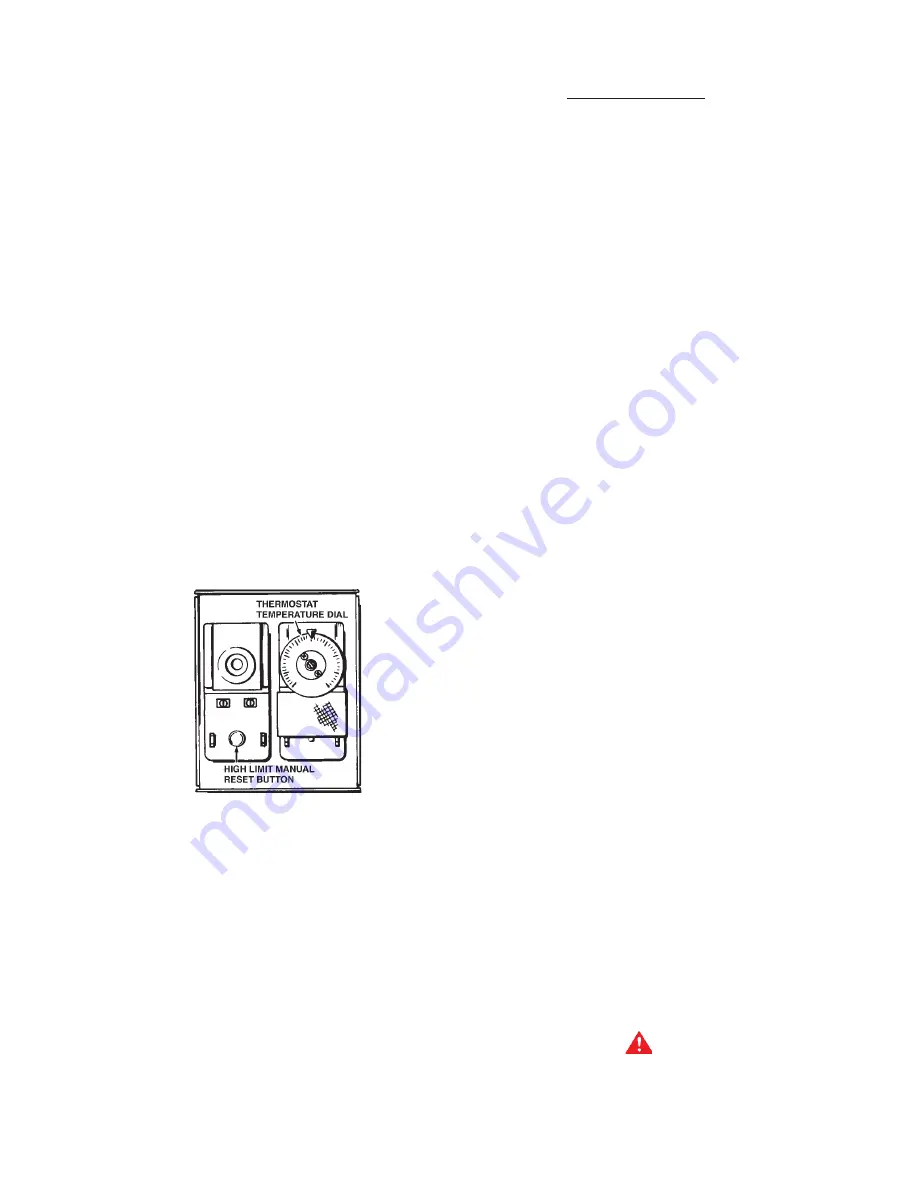

HIGH LIMIT SWITCH (E.C.O.)

The dual bulb controller ((fig. 1) contains the high limit (energy

cutoff) sensor. The high limit switch interrupts main burner gas

flow should the water temperature reach 205°F (96°C).

In the event of high limit switch operation, the appliance cannot

be restarted unless the water temperature is reduced by at least

20°F (11°C) and the high limit reset button on front of limit control

(fig.1) is depressed.

DUAL-BULB THERMOSTAT (COVER REMOVED)

FIGURE 1

Continued manual resetting of high limit control, preceded by

higher than usual water temperature is evidence of high limit switch

operation. The following is a possible reason for high limit switch

operation.

•

A malfunction in the thermostatic controls would allow the gas

valve to remain open causing water temperature to exceed

the thermostat setting. The water temperature would continue

to rise until high limit switch operation.

Contact your dealer or servicer if continued high limit switch

operation occurs, to determine the reason for operation.

CIRCULATING PUMP

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the heater.

Refer to the piping diagrams at rear of manual for electrical

hookup information and install in accordance with the latest

version of the National Electric Code ANSI/NFPA No. 70.

Only all bronze circulators are used with commercial water heaters.

Although circulators are oiled and operated by the manufacturer

some circulators must be oiled again before operating. Please

refer to manufacturer’s instructions.

DISHWASHING MACHINE REQUIREMENT

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water flow

pressures between 15 and 25 pounds per square inch. Flow

pressures above 25 pounds per square inch, or below 15 pounds

per square inch, will result in improperly sanitized dishes. Where

pressures are high, a water pressure reducing or flow regulating

control valve should be used in 180

0

line to the dishwashing

machine, and should be adjusted to deliver water between these

limits.

The National Sanitation Foundation also recommends circulation

of 180

0

F water. Where this is done, the circulation should be

very gentle so that it does not cause any unnecessary turbulence

inside the water heater. The circulation should be just enough to

provide 180

0

F water at the point of take-off to the dishwashing

machine. Adjust flow by means of the plug cock in the circulating

line.

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR

SUPPLY, VENTING, GAS SUPPLY AND ELECTRICAL WORK

ARE REQUIRED.

UNCRATING

Uncrate the heater by removing the outside mat and top locator.

The shipping pallet must be removed from the unit. It may be

possible to simply unbolt the base from the pallet and, with the

help of 2 or more persons, work the unit off the pallet. Some

units will be too heavy and will require the use of jacks or lifting

equipment to safely remove the pallet and move the unit into

position. Be careful when moving this heater. It will tip over

easily.

The heater is shipped with a burner and draft control. The burner

and draft control are shipped in separate cartons. They should

be installed as received without any alterations.

Discard the shipping crate and packaging cartons in an appropriate

manner.

LOCATING THE HEATER

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES

SUCH AS GAS WATER HEATERS IN ROOMS, GARAGES OR

OTHER AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE

STORED, OPERATED OR REPAIRED. FLAMMABLE VAPORS