6

•

Do not expose the tubular motor to crushing, impact, falling or contact with any liquids.

Do not punch holes in the entire length of the tube (motor casing) or attach screws to it.

•

Please use suitable suspension springs to fasten the roller shutter curtain to the roller shutter shaft.

You will find suitable suspension springs on page 23 and in our store under mounting accessories.

•

Important for motor type 3T35-RB (SW40):

It is essential to use mini suspension springs for motor operation. These special mini springs protrude only approx.

1 mm into the shaft. This allows the shaft to rotate freely. When using commercially available suspension springs

the motor housing is left with grinding marks because the suspension pin protrudes too far into the roller shutter shaft,

which leads to damage and destruction of the motor.

•

For steel shafts with a width across flats of 40 mm (SW40), only use shafts with

an external fold. Steel shafts with an internal fold will damage and destroy the motor.

•

Grinding marks of any kind on the motor housing will void the warranty.

•

The inspection cover of the roller shutter box must be easily accessible and removable.

•

We recommend using a tubular motor with a power 10% higher than the weight of the shutter,

to compensate for the frictional resistance of the rail guide.

>

See Guideline / Determine torque (page 3)

•

The motor is designed for short-time operation (4 min). It has an internal thermal circuit breaker which interrupts

the power supply in the event of overheating, e.g. as a result of continuous operation. The cooling phase is min. 10 min,

the thermal switch resets automatically. Regular operation is only possible after the the motor has cooled down completely.

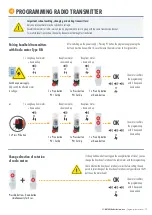

Mini suspension springs (Page 23)

8-sided shaft SW40

with external fold

Do not use

8-sided shaft SW40

with internal fold!

Before installation, all non-essential electrical wiring must be removed, all mechanisms

that are not necessary for motorized operation must be deactivated.

INSTALLATION NOTES

3T-MOTORS Radio tubular motors

| Installation notes