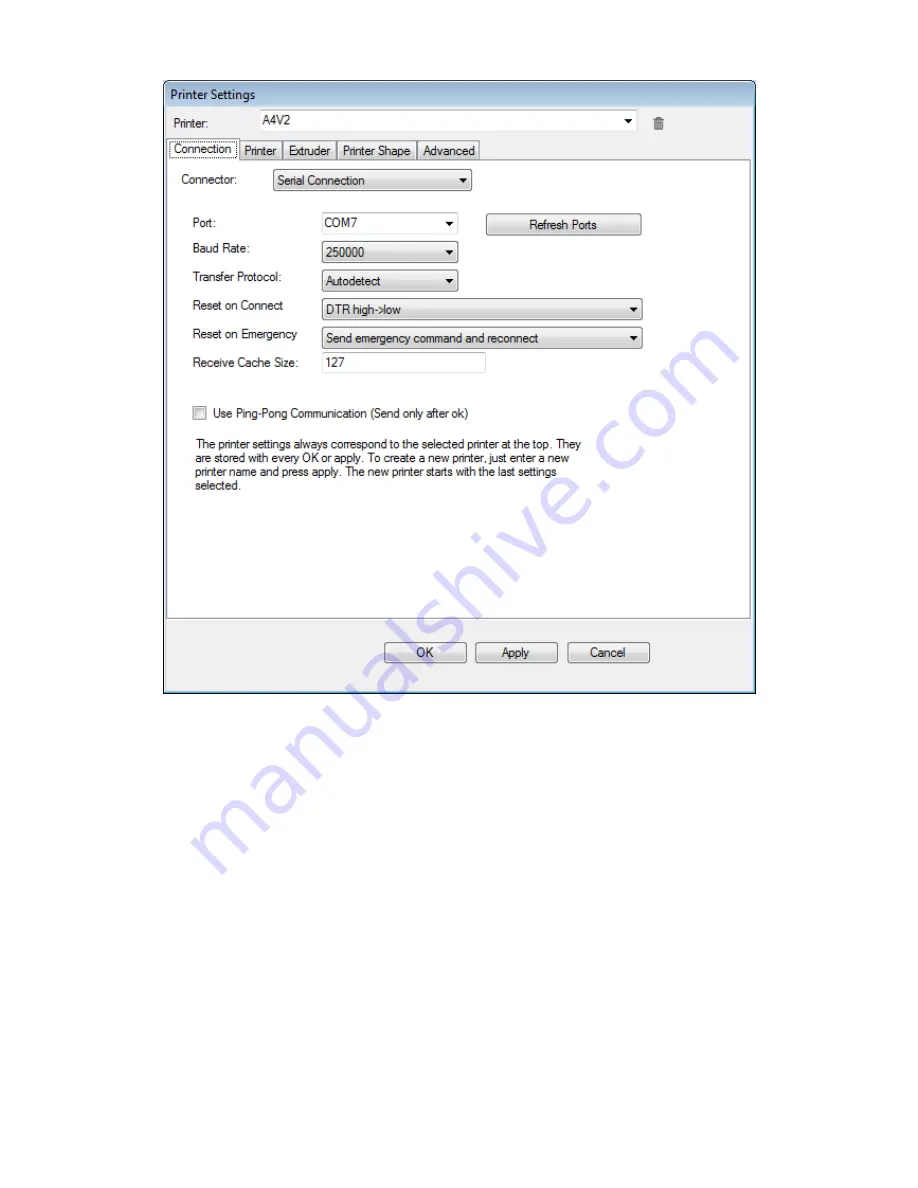

Connector: usually must be left on “Serial connection”.

Port: select the port you will use to connect to the printer. The above shown is just an example: according to

the periperals connected to your PC (inkjet printer, mouse, webcam, camera, smartphone,...), the printer will be

connected to a surely different port number. You can use the REFRESH PORTS button to force an immediate

update of available USB ports list.

Baud rate: set it to 250000

Other parameter must be left unchanged at default values (see fig.1).

15

Fig. 18: Connection parameters