11

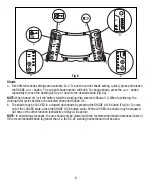

due to ambient light. In this case decrease the sensitivity. The sensitivity cannot be adjusted when in

LOCKED mode.

NOTE:

The higher the sensitivity setting, the higher the sensitivity. At the highest sensitivity, even the smallest

amount of light change (light from surrounding welders, strobe lights, reflected glare, etc.) will trigger the welding

filter to darken. If the welding filter is triggering when it is not supposed to, a lower sensitivity setting may be

needed.

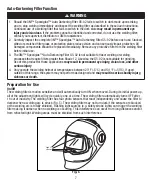

Delay

The delay function allows the user to manually increase or decrease the recovery delay time (going from dark,

back to light) according to the requirements of the welding process to reduce eye fatigue. A longer delay may

help protect the eyes from the bright light of a large, hot weld puddle. G5-02 has six different settings.

a. To see the current delay setting, quickly press and release the DELAY button. The current delay number will

blink. To change the delay, press the DELAY button repeatedly to move the flashing LED up to the desired

delay. Once the DELAY reaches level 6, press the DELAY button and it will cause the welding filter to cycle

back to level 1 (Fig. 6d).

Bluetooth

®

The welding filter can be paired with and connected to iOS™ and Android™ devices via the 3M™ Connected

Equipment App using Bluetooth® (Fig. 6e). The app can be downloaded from the iOS™ App Store® or Google

Play™ store. For information on how to connect the app with the welding filter, follow the

User Instructions

in the

app. When connected to the iOS™ or Android™ device, the user will have access to welding filter settings, work

statistics, etc.

Low Battery Indicator

The battery should be replaced when the low battery indicator flashes or LEDs do not flash when the buttons

are pressed (Fig. 6f). See the

Inspection & Maintenance

section for information regarding removing the

welding filter and replacing the battery.

INSPECTION & MAINTENANCE

W

WARNING

1.

Do not use with parts or accessories other than those manufactured by 3M as described in these

User

Instructions

.

2.

Failure to follow these instructions

may reduce the capability of the 3M™ Speedglas™ Welding

Helmet G5-02 shell to withstand impact and penetration and

may result in serious bodily injury or

death.

a. Any part of the welding helmet damaged due to significant impact should be replaced.

3.

The used battery/worn out product parts should be disposed of according to local regulations. The welding

filter should be disposed of as electronic waste.

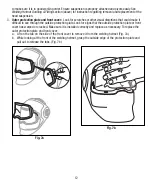

Before and after each use, inspect entire welding helmet for signs of damage or wear including dents, rips,

cracks, color changes, chalking, fading, flaking and/or penetration. Carefully inspect all helmet components

including the following:

1.

Welding Helmet Shell:

Look for visible damage including dents, cracks, color change, chalking, fading,

flaking and/or penetration. Any welding helmet subjected to significant impact should be removed from

service and replaced even if damage is not readily apparent.

2.

Headgear Suspension:

Look for cracks, rips, fading, or other damage. Ensure headgear suspension ratchet

operates properly. Inspect the overhead plastic adjustment straps for cracks or damage. Look at sweatband