10

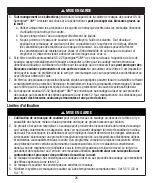

Table 2 Continued. Recommended Guide for Shade Numbers (Adapted from ANSI Z49.1-2012)

Operation

Electrode Size in.

(mm)

Arc Current

(Amps)

Minimum

Protective

Shade

Recommended*

Shade Number

Torch Brazing (TB)

—

—

3-4

Torch Soldering (TS)

—

—

2

Carbon Arc Welding (CAW)

—

—

14

Operation

Plate Thickness in.

(mm)

Recommended*

Shade Number

Oxyfuel Gas Welding (OFW)

Light

< 1/8 (< 3)

—

—

4-5

Medium

1/8 - 1/2 (3-13)

—

—

5-6

Heavy

> 1/2 (> 13)

—

—

6-8

Oxygen Cutting (OC)

Light

< 1 (< 25)

—

—

3-4

Medium

1-6 (25-150)

—

—

4-5

Heavy

> 6 (> 150)

—

—

5-6

*As a rule of thumb, start with a shade that is too dark to see the weld zone. Then go to a lighter shade which

gives sufficient view of the weld zone without going below the minimum. In oxyfuel gas welding, cutting, or

brazing where the torch and/or the flux produces a high yellow light, it is desirable to use a filter lens that

absorbs the yellow or sodium line of the visible light spectrum.

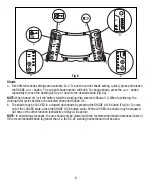

Sensitivity Selection

The sensitivity of the arc detection system can be adjusted to accommodate a variety of welding processes and

workplace conditions.

a. In order to see the current sensitivity setting, quickly press and release the SENS

+

or

-

button. The current

sensitivity number will blink. To change sensitivity, press the SENS

+

or

-

button repeatedly to move the

flashing LED up or down to the desired sensitivity (Fig. 6c).

b. The settings correspond to:

6 High – Most sensitive, for low energy TIG welding or where part of the arc may be obscured from view

5 Medium High – Very low current welding, use of TIG welding machines.

4 Medium – For low current welding, use of TIG welding machines.

3 Normal – For low current, with stable welding arcs or bright ambient light.

2 Low – Used for most types of welding.

1 Very Low – Least sensitive setting. Used if there is interference from other welders’ arcs in the vicinity.

c. If the welding filter does not switch to the dark state during welding as desired, increase the sensitivity.

Should the sensitivity be set too high, the welding filter may remain in the dark state after welding is stopped