NA - ENG

April 2016

3M-Matic

™

7000r-7000r3 Pro

Page 23

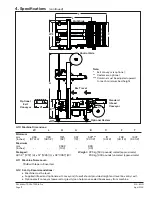

4. Pneumatic connection.

a. Read and remove safety tag from

pneumatic

“On/O

ff

” valve.

b. Connect the main air supply line to

the inlet side of the on/o

ff

valve

using

the

barbed

fi

tting and hose

clamp

provided

(See Figure 7-7B)

.

The customer supplied air hose

(8mm [5/16 inch] must be clamped

tightly to the barbed

fi

tting.

If another type of connector is

desired,

the

barbed

fi

tting can be

removed and replaced with the de-

sired 1/4-18 NPT threaded connector.

Always turn the air valve

“O

ff

”

when

the air supply line is being connected

or

disconnected.

5. Turn the air supply on by turning the

air

on/o

ff

valve to SUP (On).

6. Raise and latch upper drive assembly

in full “Up” position.

Note –

Read “Operation –

Mechanical Latch” before

raising and latching upper

drive

assembly.

Machine Set-Up

The following instructions are presented in

the

order

recommended for setting up and

installing the case sealer, as well as for

learning the operating functions and

adjustments. Following them step by step

will result in your thorough understanding

of the machine and an installation in your

production line that best utilizes the many

features built into the case sealer.

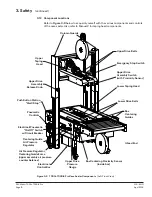

Refer

to

Figure 7-14

to identify the various

components of the case sealer.

1. Install the upper tape drum bracket

on top crossbar as shown in

Figure 7-7A

.

2. Mount the column guards, shown in

Figure 7-7

. Remove and retain the

screws and washers holding the guards

on the columns for reinstallation after

Bumper Supports have been mounted

(see Column Bumper Installation in

the Installation and Set-Up Section

and Special Set-Up Procedures

Section

/

Figure 7-7 and Section 13

).

After the Bumpers have been

installed, the Column Guards must

be installed -

Figure 7-7

) for safe

operation of the machine.

Replace existing screws and washers

to secure the guards in place.

3. Cut cable ties securing upper assem-

bly to machine bed on each side.

Important –

Use care when working

with compressed air.

See

Speci

fi

cations for compressed air

supply needs. As shown in

Figure 7-15

,

an

on/o

ff

valve, pressure regulator, and

fi

lter are provided to service the air supply.

Note –

A precision regulator is used

to balance the upper drive assembly.

Due to the self relieving feature of this

regulator a small amount of air will

continually vent to the atmosphere.

This is normal and amounts to

approximately 3 litre/min. [0.1 SCFM].

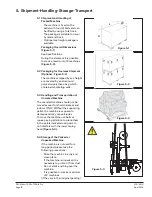

- Allow only properly trained and qualifi ed

personnel to operate and service this

equipment.

WARNING

• To reduce the risk associated

with impact hazards:

-

Always use appropriate supporting

means when working under the

upper drive assembly

WARNING

7. Installation

(continued)

Summary of Contents for 3M-Matic 7000r

Page 2: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page ii ...

Page 4: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page iv ...

Page 6: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page vi ...

Page 8: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page viii ...

Page 10: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page x ...

Page 30: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 18 ...

Page 62: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 50 ...

Page 64: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 52 ...

Page 72: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 60 ...

Page 92: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 80 ...

Page 94: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page ii ...

Page 96: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page iv ...

Page 98: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page vi ...

Page 102: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 2 ...

Page 120: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 20 ...

Page 122: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 22 ...

Page 140: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 40 ...

Page 141: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 41 ...

Page 142: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 42 ...

Page 144: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page ii ...

Page 146: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page iv ...

Page 148: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page vi ...

Page 152: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 2 ...

Page 170: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 20 ...

Page 172: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 22 ...

Page 190: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 40 ...

Page 191: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 41 ...

Page 192: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 42 ...