NA - ENG

April 2016

3M-Matic

™

7000r-7000r3 Pro

Page 44

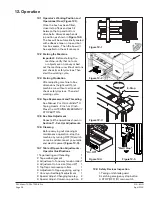

13.9 Box Drive Pulley Rings

Before installing a new belt,

check the orange plastic drive

pulley rings for wear. If torn,

broken, or worn smooth, replace

the

rings

(Figure 13-3).

13.10 Box Drive Belt Tension

The four (4) continuously moving

drive belts convey boxes through

the tape applying mechanism.

The box drive belts are powered

by an electric gear motor.

Tension adjustment of these belts

may be required during normal

operation (for Belt Tension Adjust-

ment - refer to

Box Drive Belt

Replacement

). Belt tension must

be adequate to positively move

the box through the machine and

the belts should run fully on the

surface of the pulleys at each end

of the frame. The idler pulleys on

the infeed end are adjusted in or

out to provide proper belt tension.

Each belt is adjusted separately.

Belt tension is obtained by tight-

ening the adjustment screw so

that a moderate pulling force of

3.5kg [7lbs.] applied at the mid

span, as shown in

Figure 13-4

,

will

de

fl

ect the belt 25mm [1 inch].

This will assure positive contact

between the belt and the drive

pulley on the discharge end of

the drive assembly.

Figure 13-4 Box Drive Belt Tension Adjustment

Discharge End

Infeed End

3.5kg (7lbs) Pull Force

with 25mm (1 inch) at Mid span

Box Drive Belt

Figure 13-3

• To reduce the risk associated with

mechanical and electrical hazards:

- Turn peumatic and electrical supplies off

and disconnect before performing any

adjustments, maintenance or servicing

the machine or taping heads.

WARNING

13. Maintenance and Repairs

(continued)

Summary of Contents for 3M-Matic 7000r

Page 2: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page ii ...

Page 4: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page iv ...

Page 6: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page vi ...

Page 8: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page viii ...

Page 10: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page x ...

Page 30: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 18 ...

Page 62: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 50 ...

Page 64: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 52 ...

Page 72: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 60 ...

Page 92: ...NA ENG April 2016 3M Matic 7000r 7000r3 Pro Page 80 ...

Page 94: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page ii ...

Page 96: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page iv ...

Page 98: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page vi ...

Page 102: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 2 ...

Page 120: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 20 ...

Page 122: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 22 ...

Page 140: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 40 ...

Page 141: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 41 ...

Page 142: ...NA ENG April 2016 3M Matic Accuglide 3 2 Inch Taping Head Page 42 ...

Page 144: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page ii ...

Page 146: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page iv ...

Page 148: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page vi ...

Page 152: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 2 ...

Page 170: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 20 ...

Page 172: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 22 ...

Page 190: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 40 ...

Page 191: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 41 ...

Page 192: ...NA ENG April 2016 3M Matic Accuglide 3 3 Inch Taping Head Page 42 ...