PAGE 34

OCT-16

17. OPERATIONAL PROBLEMS OF THE SPRAYER

Working troubles are in experience mostly the same:

-

Bad joints in the suction area (between tank and pump) cause lower pump capacities

or prevent the sucking

-

A dirty suction filter can cause lower pump capacities

-

A dirty pressure filter causes a pressure increase on the pump and a reduction on the

nozzles

-

Larger particles can jam in the pump and lower the capacity

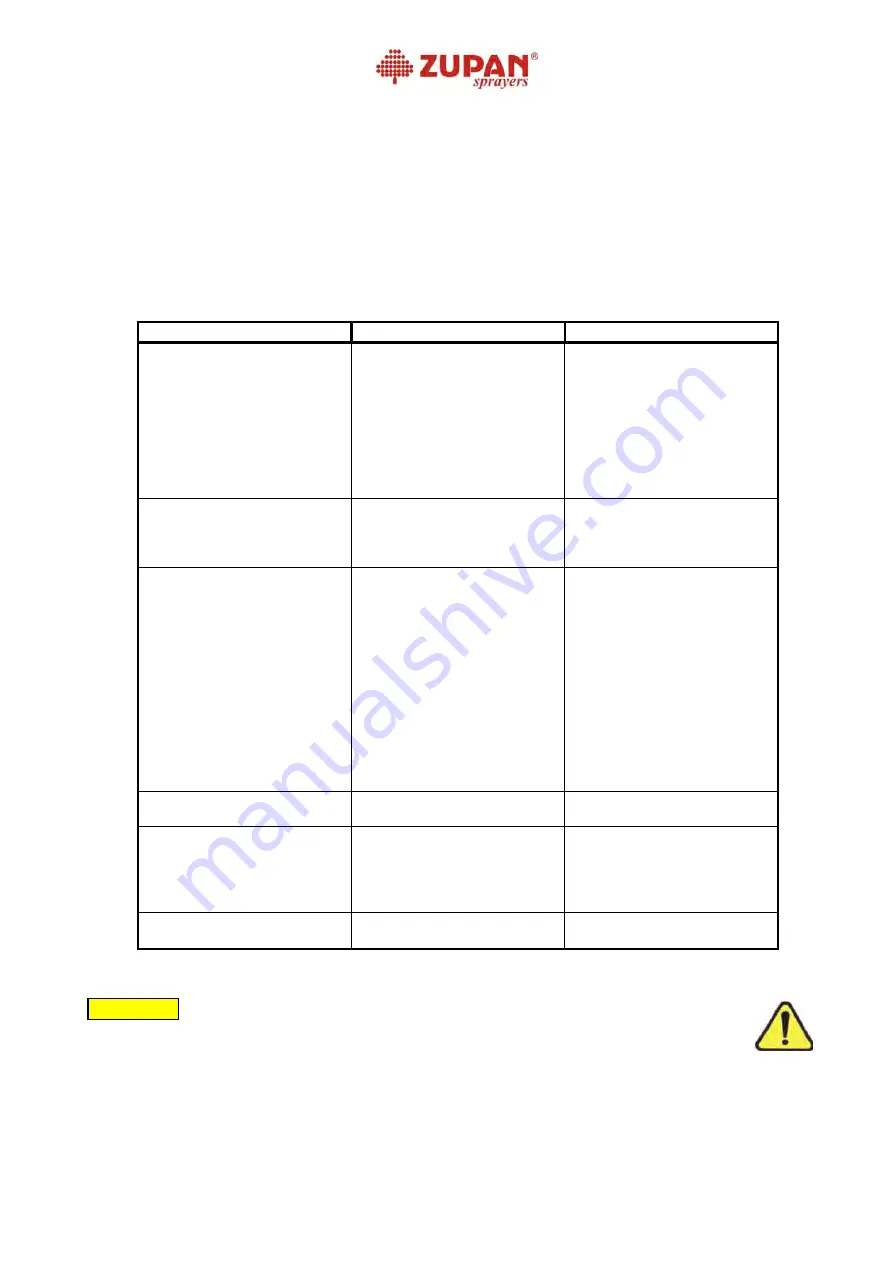

Fault

Cause

Control/remedy

No fluid is flowing from the

nozzles after you opened the

system

Pouring in the sucking area

Air in the system

A dirty sucking or pressure

filter

Check the valve before the

sucking filter.

Check the joints and the

suction hoses.

Check the membranes.

Rotate the handle of the

regulating valve in different

ways.

Clean the filters.

Irregular pressure

Hydraulic mixer

Pump valves

Bad manometer

Engage the hydraulic mixing.

Check the valves and their

wear.

Change the manometer.

Pressure drop

Dirty filters

Wear nozzles

The valve on the tank lid

stuffed up

Air sucking while you have

few fluid in the tank

Clean all filters and system

with clean water.

When working with powder

agents check if the hydraulic

mixer in on.

Check the nozzle flow and if it

is deviating, more than 10%

change them.

Close the valve of the

hydraulic mixer.

Pressure is raising

The hydraulic mixer stuffed

up

Clean the nozzle in the

hydraulic mixer.

Hard foam fluid

Sucking air in the system

Too hard mixing

Check the joints in the

sucking area

Close the hydraulic mixer

Lower the P.T.O. rpm

Add an anti foam agent

The fluid is flowing out of the

pump housing

Crack in the housing or a bad

membrane

Replace the membrane or

the pump.

Check regularly:

-

that you have clean suction and pressure filters

-

suction and pressure hoses for defects

-

that all seals are in place and in good condition

-

that the manometer is not stuffed and that it indicates 0 when the

pump is not working

WARNING !

Содержание ZM 400 VCRA

Страница 10: ...PAGE 10 OCT 16 1 18 22 5 27 21 12 20 10 ...

Страница 33: ...OCT 16 PAGE 33 ...