44

Page

44

6.

Important notes for the processing of Lithium Disilicate

VARIO PRESS 300.

e

6.4 Investing

Pay attention to the attached brochure re-

garding the VARIO BALANCE dosing device.

■

The mixing bowl should be moist.

■

Choose the desired concentration

■

The components will be weighed in

the following order: Liquid, water then

powder

■

When the powder is being put into the

mixing bowl, start the timer.

■

With every investment the total set-

ting time is different

(e.g. Zubler Press-max 25min.)

■

To achieve repeatable results, all steps

should always be carried out in the

same way.

• For the same quantities, always

use the same mixing bowl.

• Using different size mixing bowls

will result in different expansion

results.

• Spatulate by hand (e.g. 10 sec.)

• Depending on the investment,

always choose the same mixing

program.

■

Using light vibration while pouring the

investment into the ring.

■

Seat the levelling top at an angle, to

avoid trapping air (blisters) at the

bottom of the ring.

■

While setting, place the filled ring in a

vibration-free place.

■

The setting time must be followed ex-

actly (e.g. 25 min for Zubler Press-Max)

6.5 Burnout furnace

Set burnout temperature to 850°C

■

Keep in mind that the distribution of

temperature depends on the volume

of the furnace chamber, the number

and position of the heating elements

and the number of the rings.

■

Maintain the burnout furnace accor-

ding to the manufacturer's instruc-

tions.

■

Check the temperatures on a regular

basis and calibrate when necessary

■

Pay attention to the correct position

of the ring inside the burnout furnace

(see schema of the burnout furnace)

■

Depending on the number of rings

inside the chamber, increase the hold

time by 15 minutes for each

additional ring.

■

When the door is opened the tempe-

rature in the burnout furnace declines

by up to 80°C, the effective holding

time starts only when the oven

reaches the set temperature

(e.g. at 850°C) for a

100g ring:

minimum 45min.

200g ring:

minimum 60min.

How to position rings in a burnout furnace

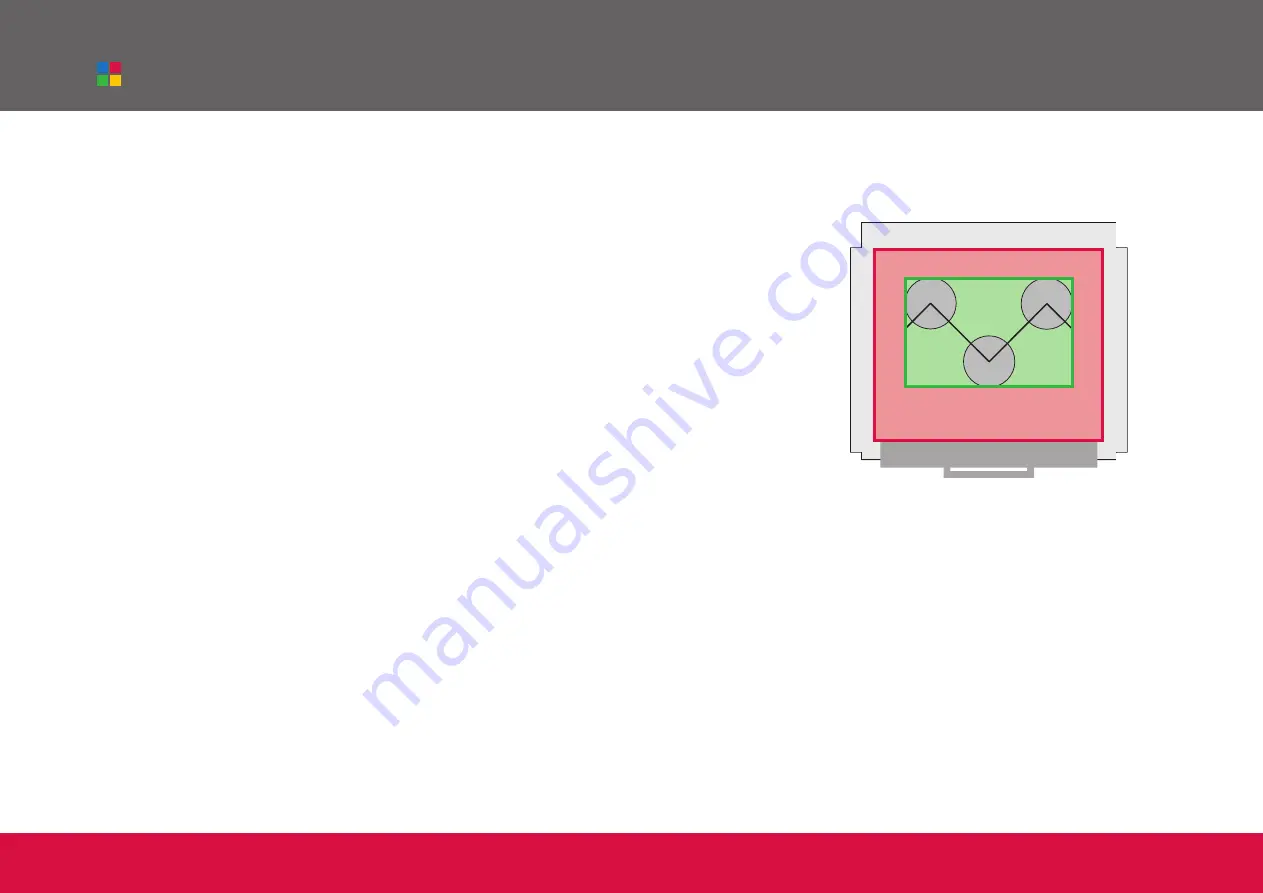

❶

The distance of the rings to the inside

walls and to each other must be at

least 2,5cm (1inch). This is shown in

the illustration as red zone 1.

➋

The door of the furnace makes a

homogeious distribution of heat

impossible. Therefore, the ring may

not be placed in the front third of the

furnace (for large furnaces, this

applies to one quarter of the front

area). This is shown in the illustrati-

on as red zone 2.

➌

Place the rings in the remaining area

of the furnace chamber left over from

points 1) and 2). This is shown in the

illustration as the green zone.

➍

To avoid the development of shades

among the rings, do not position

them in a strait line.

■

Remove the top and base of the ring

with a rotating movement.

■

Remove the investment ring from the

silicone ring former. Let the ring set

for a minimum of 1 minute to ensure

complete moisture evaporation before

placing it in the burnout furnace.

➍

➌

➋

❶

Содержание VARIO PRESS 300

Страница 2: ...Intentionaly blank...

Страница 47: ...Intentionaly blank...

Страница 49: ...49 Page Note Main menu 1...