INSTALLATION AND OPERATING INSTRUCTIONS:

2-jaw parallel gripper, hybrid, HRC-04 series

19

Zimmer GmbH

●

Im Salmenkopf 5

●

77866 Rheinau, Germany

●

+49 7844 9138 0

●

+49 7844 9138 80

●

www.zimmer-group.com

DDOC00269 / d

EN / 3/31/2020

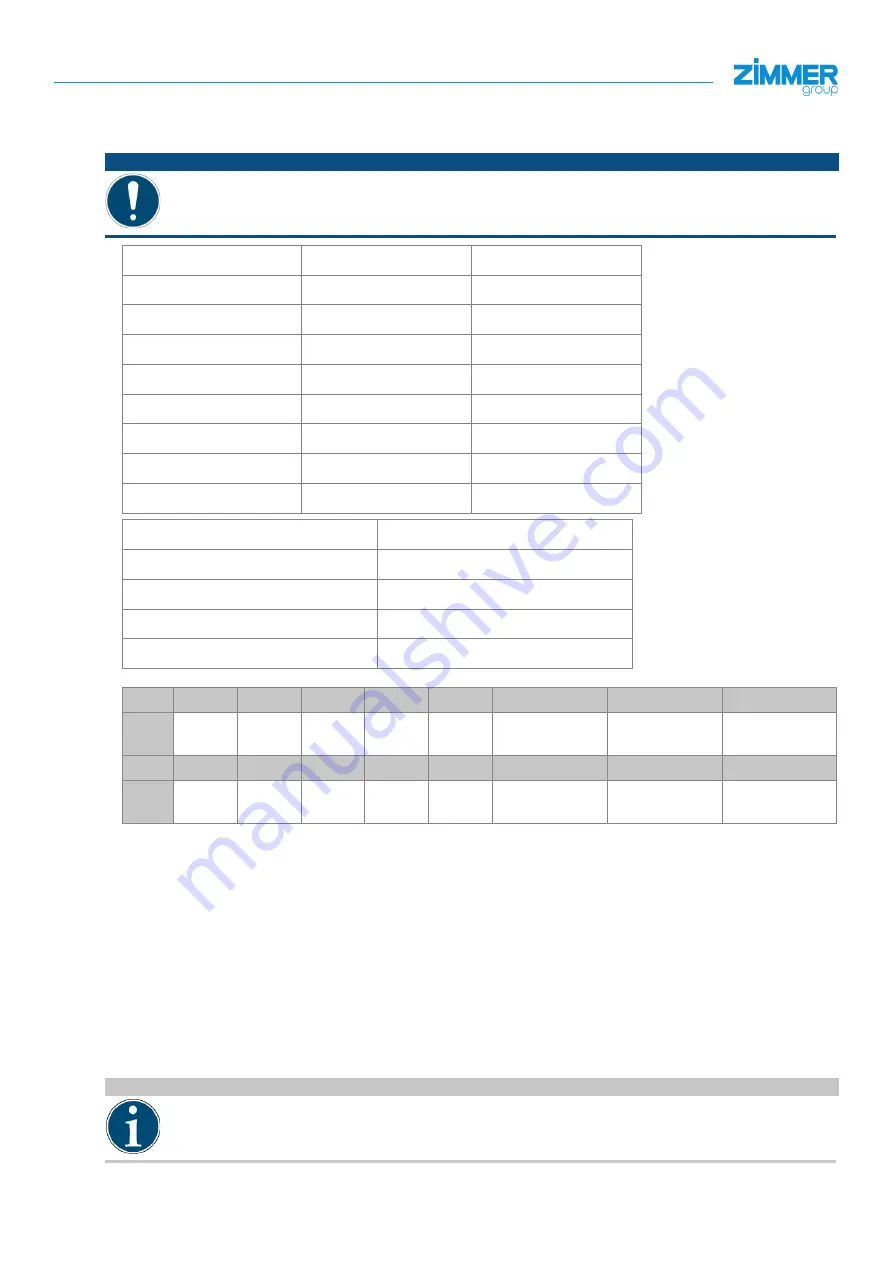

8.3 Parameter

8.3.1 „ControlWord“ parameter

NOTICE:

In the „ControlWord“ parameter, only one single bit or the value 0 may be set at a time. Only the values

listed in the following table are valid:

Parameter

Decimal value

Hexadecimal value

Data transfer

1

0 x 1

WritePDU

2

0 x 2

ResetDirectionFlag

4

0 x 4

Teach

8

0 x 8

Adjust

128

0 x 80

MoveToBase

256

0 x 100

MoveToWork

512

0 x 200

ErrorReset

32768

0x8000

Name

"ControlWord"

Data format

UINT16

Permission

Write

Transfer

Cyclical

Value range

0 to 65535

„ControlWord“ structure:

Bit 15

Bit 14

Bit 13

Bit 12

Bit 11

Bit 10

Bit 9

Bit 8

Byte 1

“Error

Reset” -

-

-

-

-

"MoveToWork" "MoveToBase"

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

"Adjust" -

-

-

"Teach" "ResetDirection-

Flag"

"WritePDU"

"Datatransfer"

Bit 0: „Datatransfer“

►

Setting this bit causes the gripper to accept the data transmitted in the process data („Workpiece-

No“ = 0) or the data stored in the workpiece data records („WorkpieceNo = 1 to 32) as the active

data set.

Bit 1: „WritePDU“

►

Setting this bit communicates to the gripper that it should write the current process data to the

selected tool recipe.

Bit 2: „ResetDirectionFlag“

► Setting this bit informs the gripper that the direction flag needs to be reset.

►

This makes a repeated movement to a position possible.

►

This is logical during a switchover of workpiece recipes.

Bit 3: „Teach“

►

Setting this bit informs the gripper to save the current position as the „TeachPosition“ in the selec-

ted „WorkpieceNo“.

INFORMATION:

This only works if there is no „0“ that is transmitted in the workpiece number!