.

5.4

Copper

Piping

(see hand out in Zellabox)

1.

Cut the pipe ends with a pipe cutter

2.

Remove burrs with the cut surface facing downwards so

that the chips do not enter the pipe

3.

Put the flare nuts on pipe

4.

Flare the pipe

5.

Check that the flaring is properly made

6

. Never use old or pre-used pipes

Zellabox

Safety

Instructions

7. Do not use mineral oil on flared part

8.

Incomplete flaring may cause gas leakage

9.

Use flare nut fixed to unit

10.

Use torque wrenches when tightening the flare nuts

11.

Protect ends from dust

12.

Use pipe bender

10.

NEVER use pipes thinner than 0.8mm even when it is

available on the market.

Refrigerant Piping Work

1.

Flaring the pipe end.

1) Cut the pipe end with a pipe cutter.

2) Remove burrs with the cut surface facing

downward so that the chips do not enter the pipe.

3) Put the flare nut on the pipe.

4) Flare the pipe.

5) Check that the flaring is properly made.

1) Do not use mineral oil on flared part.

2) Prevent mineral oil from getting into the system as this would reduce the unit life.

3) Never use piping which has been used for previous installations. Only use parts which are provided with the unit.

4) Do never install a refrigerant drier to this unit.

5) The drying material may dissolve and damage the system.

6) Incomplete or improper flaring may cause refrigerant gas leakage.

WARNING

2.

Refrigerant piping.

1) Use the flare nut fixed to the main unit. (To prevent cracking of the flare nut by aged deterioration.)

2) To prevent gas leakage, apply refrigeration oil only to the inner surface of the flare. (Use refrigeration oil for R410A.)

3) Use torque wrenches when tightening the flare nuts to prevent damage to the flare nuts and gas leakage.

CAUTION

Align the centers of both flares and tighten the flare nuts 3 or 4 turns by hand. Then tighten them fully with the torque wrenches.

2-1. Caution on piping handling

1) Protect the open end of the pipe against dust and moisture.

2) All pipe bends should be as gentle as possible.

Use a pipe bender for bending.

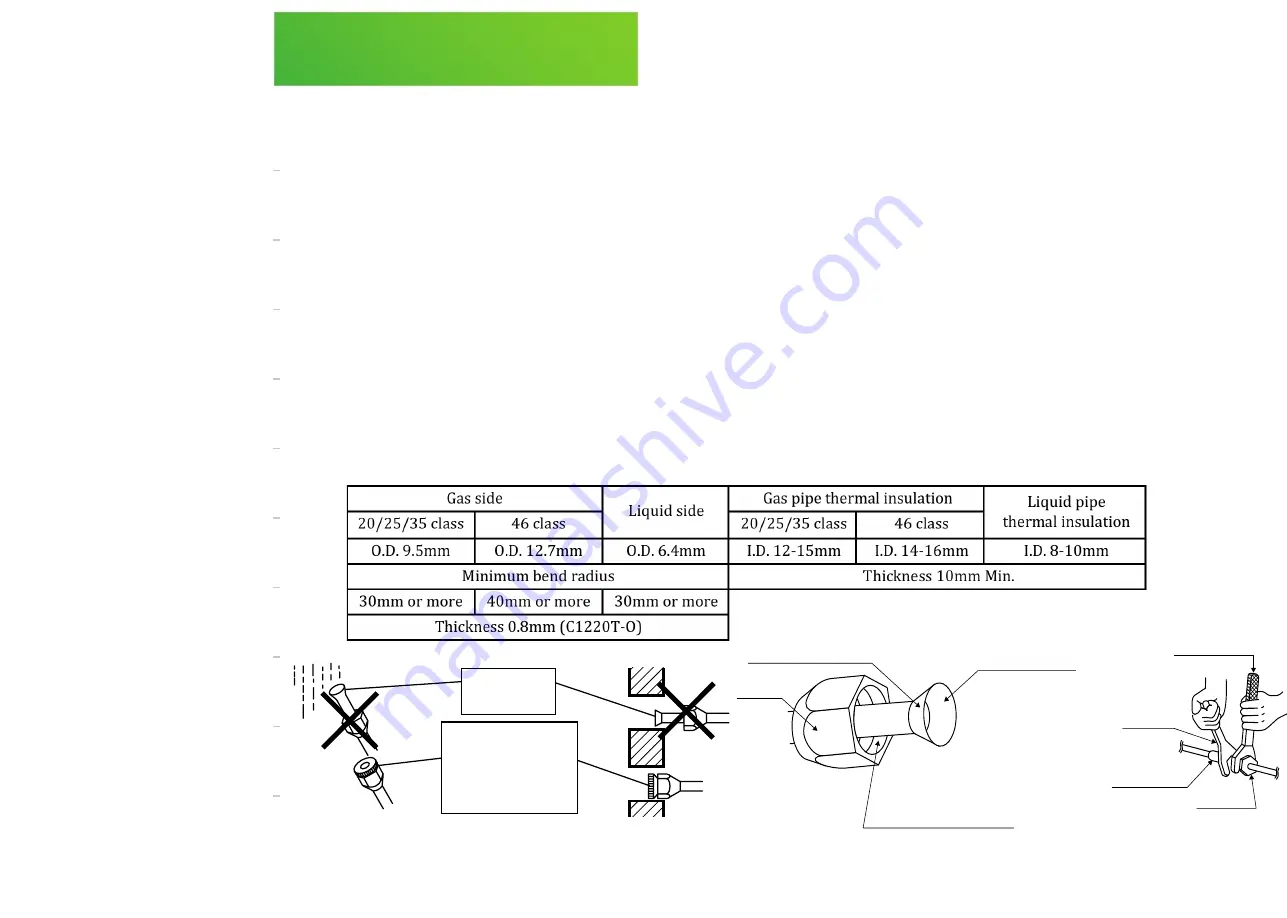

2-2. Selection of copper and heat insulation materials

• When using commercial copper pipes and fittings, observe the following:

1) Insulation material: Polyethylene foam

Heat transfer rate: 0.041 to 0.052 W/mK (0.024 to 0.030 Btu/fth˚F (0.035 to 0.045kcal/mh˚C))

Refrigerant gas pipe’s surface temperature reaches 230˚F (110˚C) max.

Choose heat insulation materials that will withstand this temperature.

2) Be sure to insulate both the gas and liquid piping and to provide

insulation dimensions as below.

3) Use separate thermal insulation pipes for gas and liquid refrigerant pipes.

Flare nut tightening torque

Gas side

Liquid side

1/2 inch

5/8 inch

1/4 inch

36.5- 44.5ft • Ibf

(49.5-60.3N • m)

45.6-55.6ft • Ibf

(61.8-75.4N • m)

10.4 -12.7ft • Ibf

(14.2-17.2N • m)

Gas side

Liquid side

15/18/24 class

O.D. 1/4 inch (6.4mm)

Gas pipe thermal insulation

Thickness 0.393 inch (8mm) Min.

Thickness 0.031 inch

(0.8mm) (C1220T-O)

Thickness 0.039 inch

(1.0mm) (C1220T-O)

Thickness 0.031 inch

(0.8mm) (C1220T-O)

1-9/16 inch (40mm) or more 1-15/16 inch (50mm) or more 1-3/16 inch (30mm) or more

Minimum bend radius

24 class

O.D. 5/8 inch (15.9mm)

15/18 class

I.D. 0.551-0.630 inch

(14-16mm)

24 class

I.D. 0.630-0.709 inch

(16-20mm)

Liquid pipe thermal insulation

15/18 class

O.D. 1/2 inch (12.7mm)

15/18/24 class

I.D. 0.315-0.393 inch

(8-10mm)

(Cut exactly at

right angles.)

Remove burrs

Check

Flare’s inner

surface must

be flaw-free.

The pipe end must

be evenly flared in

a perfect circle.

Make sure that the

flare nut is fitted.

Set exactly at the position shown below.

A

Flaring

Die

A 0-0.020 inch (0-0.5mm)

Clutch-type

Flare tool for R410A

0.039-0.059 inch (1.0-1.5mm)

Clutch-type (Rigid-type)

0.059-0.079 inch (1.5-2.0mm)

Wing-nut type (Imperial-type)

Conventional flare tool

Do not apply refrigeration

oil to the outer surface.

Flare nut

Apply refrigeration

oil to the inner

surface of the flare.

Do not apply refrigeration

oil to the flare nut avoid

tightening with over torque.

[Apply oil]

Torque wrench

Piping union

Flare nut

Spanner

[Tighten]

Wall

If no flare cap is

available, cover the

flare mouth with

tape to keep dirt or

water out.

Be sure to

place a cap.

Rain

Gas pipe

Liquid pipe

Gas pipe

insulation

Liquid pipe

insulation

Finishing tape

Drain hose

Inter-unit wiring

Refrigerant Piping Work

1.

Flaring the pipe end.

1) Cut the pipe end with a pipe cutter.

2) Remove burrs with the cut surface facing

downward so that the chips do not enter the pipe.

3) Put the flare nut on the pipe.

4) Flare the pipe.

5) Check that the flaring is properly made.

1) Do not use mineral oil on flared part.

2) Prevent mineral oil from getting into the system as this would reduce the unit life.

3) Never use piping which has been used for previous installations. Only use parts which are provided with the unit.

4) Do never install a refrigerant drier to this unit.

5) The drying material may dissolve and damage the system.

6) Incomplete or improper flaring may cause refrigerant gas leakage.

WARNING

2.

Refrigerant piping.

1) Use the flare nut fixed to the main unit. (To prevent cracking of the flare nut by aged deterioration.)

2) To prevent gas leakage, apply refrigeration oil only to the inner surface of the flare. (Use refrigeration oil for R410A.)

3) Use torque wrenches when tightening the flare nuts to prevent damage to the flare nuts and gas leakage.

CAUTION

Align the centers of both flares and tighten the flare nuts 3 or 4 turns by hand. Then tighten them fully with the torque wrenches.

2-1. Caution on piping handling

1) Protect the open end of the pipe against dust and moisture.

2) All pipe bends should be as gentle as possible.

Use a pipe bender for bending.

2-2. Selection of copper and heat insulation materials

• When using commercial copper pipes and fittings, observe the following:

1) Insulation material: Polyethylene foam

Heat transfer rate: 0.041 to 0.052 W/mK (0.024 to 0.030 Btu/fth˚F (0.035 to 0.045kcal/mh˚C))

Refrigerant gas pipe’s surface temperature reaches 230˚F (110˚C) max.

Choose heat insulation materials that will withstand this temperature.

2) Be sure to insulate both the gas and liquid piping and to provide

insulation dimensions as below.

3) Use separate thermal insulation pipes for gas and liquid refrigerant pipes.

Flare nut tightening torque

Gas side

Liquid side

1/2 inch

5/8 inch

1/4 inch

36.5-44.5ft • Ibf

(49.5-60.3N • m)

45.6-55.6ft • Ibf

(61.8-75.4N • m)

10.4 -12.7ft • Ibf

(14.2-17.2N • m)

Gas side

Liquid side

15/18/24 class

O.D. 1/4 inch (6.4mm)

Gas pipe thermal insulation

Thickness 0.393 inch (8mm) Min.

Thickness 0.031 inch

(0.8mm) (C1220T-O)

Thickness 0.039 inch

(1.0mm) (C1220T-O)

Thickness 0.031 inch

(0.8mm) (C1220T-O)

1-9/16 inch (40mm) or more 1-15/16 inch (50mm) or more 1-3/16 inch (30mm) or more

Minimum bend radius

24 class

O.D. 5/8 inch (15.9mm)

15/18 class

I.D. 0.551-0.630 inch

(14-16mm)

24 class

I.D. 0.630-0.709 inch

(16-20mm)

Liquid pipe thermal insulation

15/18 class

O.D. 1/2 inch (12.7mm)

15/18/24 class

I.D. 0.315-0.393 inch

(8-10mm)

(Cut exactly at

right angles.)

Remove burrs

Check

Flare’s inner

surface must

be flaw-free.

The pipe end must

be evenly flared in

a perfect circle.

Make sure that the

flare nut is fitted.

Set exactly at the position shown below.

A

Flaring

Die

A 0-0.020 inch (0-0.5mm)

Clutch-type

Flare tool for R410A

0.039-0.059 inch (1.0-1.5mm)

Clutch-type (Rigid-type)

0.059-0.079 inch (1.5-2.0mm)

Wing-nut type (Imperial-type)

Conventional flare tool

Do not apply refrigeration

oil to the outer surface.

Flare nut

Apply refrigeration

oil to the inner

surface of the flare.

Do not apply refrigeration

oil to the flare nut avoid

tightening with over torque.

[Apply oil]

Torque wrench

Piping union

Flare nut

Spanner

[Tighten]

Wall

If no flare cap is

available, cover the

flare mouth with

tape to keep dirt or

water out.

Be sure to

place a cap.

Rain

Gas pipe

Liquid pipe

Gas pipe

insulation

Liquid pipe

insulation

Finishing tape

Drain hose

Inter-unit wiring

Please note: Pipe size is 9.5mm for cooling capacity 2kw up to 3.5kw (See enclosed

manual with condenser)

5 Single & Dual cooling

system

commissioning

steps:

12

Содержание Cubb

Страница 1: ...1 Zellabox Installation Manual...

Страница 20: ...Warning Fire Suppression System Information 20...