6.2 CLEANING AND INSPECTING THE Octo-Z

6.2.1 Rinse all plastic and silicone parts in fresh warm soapy water solution. Rinse with clean warm water

and then blow the parts dry with compressed air to remove any sand and dust particles.

! WARNING !

DO NOT

use vinegar or other acid solutions on the plastic parts since this will

. cause the plastic to become brittle!

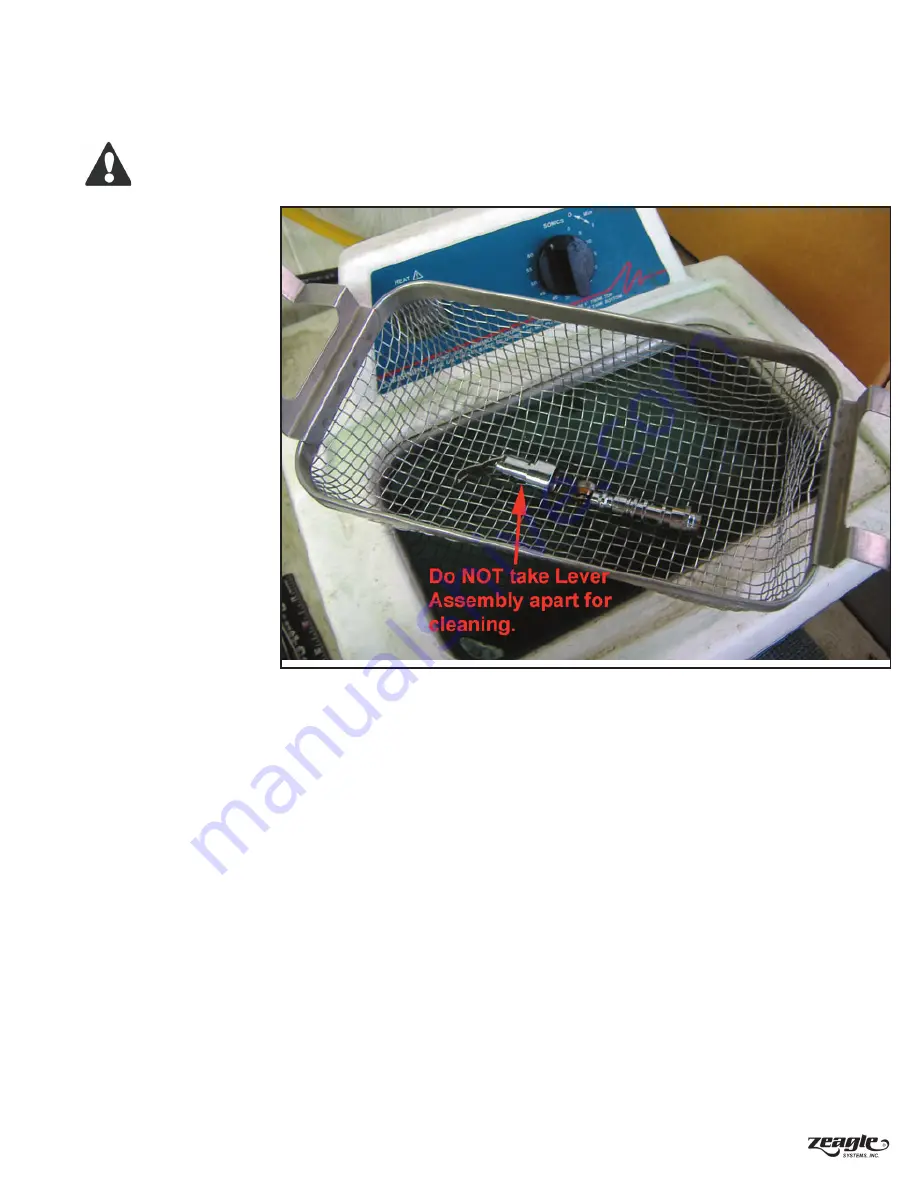

6.2.2 If necessary because of deposits or corrosion, clean all metal parts of the Octo-Z in an ultrasonic

cleaner or cleaning solution (See Photo 19). See Section 10.1 for recommendations on cleaning solutions.

6.2.3 Inspect the Body (25) for any cracks or nicks. Look particularly closely at the area where the exhaust

valve (14) seals and where the bushing (8) clamps. Replace the housing if any cracks are found.

6.2.4 Inspect the sealing surface on the Seat (14), where the seating seal (13) seals, for any nicks or

scratches. Replace the seat (14) if any serious defects are found at the sealing area, or if the threads appear

worn out. Simple corrosion due to poor rinsing by the owner can be removed with an old toothbrush.

6.2.5 Blow all dust and debris out of the Seat (14) (also known as the orifice) with clean compressed air.

6.2.6 Inspect the exhaust valve (40) and the Valve Support (39). Look carefully at the base of the barbed

nipple where it comes out of the middle of the valve. Look for any tearing at this point. Replace the valve

if any tears are found. Replace the valve if nicks or tears are found at the sealing edges of the valve.

6.2.7 During the Bi-annual Overhaul, all parts included in the Annual Service Kit (345-7000) are replaced no

matter what the condition of those parts. Carefully examine all other parts of the Octo-Z for signs of dete-

rioration. Replace those parts too where necessary

17

Photo 19