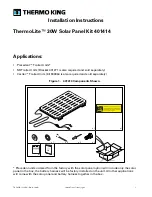

TERMINAL LAYOUT AND WIRING

This graph is for upright

instruments with

dimension A, C, E.

For instruments with

dimension B, F, just

clockwise rotate the

graph for 90 degree,

and the terminal

numbers keep

unchanged.

AU1

M1

M2/MIO

AUX

ALM

COMM

AL2

1

2

3

4

5

6

7

8

9

10

11

12

15

16

17

18

19

20

13

14

AL1

AU2

COM

COM

N/C

N/O

N/O

N/O

+

+

A

B

+

100-240VAC~

+

+

OUTP/M3

COM

COM

N/O

N/C

N/O

N/O

COM

N/C

N/O

+

+

COM

COM

N/O

N/O

N/O

N/C

+

+

IN3

IN2

IN1

CJC

+

+

OP2/IN6

OP1/IN5

IN4

IN3

IN2

IN1

Thermocouple wiring:

When wiring a thermocouple input, the compensation wire should be qualified and directly

connect to the corresponding terminals in correct direction. When M1 module is installed in

J1 socket, a Cu50 resistor can be connected between terminal 17 and 20 to compensate the

cold junction; short connection between terminal 17 and 20 can realize ice-point

compensation.

Two-wire RTD wiring:

RTD can select two-wire or three-wire method by B of “AF” parameter. Two-wire method

enable to input two channel signals in one module, but user has to measure and calculate the

resistance of the wire. To apply two-wire method, the J2 module should be installed and the

resistance of every wire should be less than 2ohm.

AI-702M/704M/706M can measure the lead wire resistance of two-wire method and save it to

parameter “Sc”. However, the lead wire resistance changes as the temperature changes.

If the lead wires has the same ambient temperature as that of the instrument and no other

resistor series connects to the lead wire, the indicators can compensate the resistance

change by measuring the ambient temperature (compensation coefficient is 0.004/

℃

);

otherwise, two-wire method is not recommended.

Three-wire RTD wiring:

Three-wire method is a traditional wiring method requiring that the resistance of the three wire

be equal. One “J0” module supports 1 three-wire RTD. Three-wire method provides higher

measurement accuracy.