- 16 -

WARNING

Improper maintenance of the log splitter may void your warranty.

ALWAYS turn off the engine,

disconnect the spark plug, and relieve system pressure before cleaning, adjusting, or repairing the

splitter. Relieve system pressure by moving Split Control Lever back and forth several times.

MAINTENANCE

•

Before performing maintenance, the log splitter must be placed in maintenance mode. Turn off

the engine, disconnect spark plug and move the control lever forward and backwards to relieve

the hydraulic pressure.

•

After performing any maintenance, make sure all guards, shields and safety features are put

back in place before operating the log splitter.

•

Before operating make sure the tires have the RECOMMENDED TIRE PRESSURE.

•

Regularly grease axle and wheel bearing area or when needed.

•

Change hydraulic oil annually or every 100 hours.

•

Periodically check all fasteners and hoses for tightness and leaks.

•

Annually clean and lightly lubricate all moving parts o

r when needed.

•

Use a glossy enamel spray paint to touch up scratched or worn painted metal surfaces.

•

Never exceed load capacity rating of 20 tons it will damage the log splitter.

•

Always inspect and clean the wedge slot on the beam every 50 hours to avoid log chips from

obstructing. Before inspecting or cleaning

ALWAYS TURN THE ENGINE OFF

.

Refer to the Engine Owner’s Manual for engine maintenance.

What

When

How

Hoses

Each Use

Inspect hoses for exposed wire mesh and leaks.

Replace all worn or damaged hoses before starting the

engine.

Hydraulic

Fittings

Each Use

Inspect fittings for cracks and leaks. Replace all

damaged fittings before starting the engine.

Nuts and Bolts

Each Use

Check for loose bolts, tighten before operating.

Beam

Each Use

Apply grease to beam surface.

Moving Parts

Each Use

Clear debris from log splitter.

Hydraulic Oil Change (Annually or 100hrs)

1. Remove the suction hose from the hydraulic tank to drain the hydraulic oil.

2. Drain hydraulic oil and fill with correct type of hydraulic oil approximately 2.64 Gallons (10L).

3. Replace the dipstick and check the oil level reads full (recheck oil level before operating).

4. Properly dispose of used oil at an oil-recycling center. Used hydraulic oil is hazardous waste.

WARNING

Dispose of the used oil and other toxic material properly. Take all used oil and waste to a

designated waste facility or collection site for proper handling or recycling.

DO NOT dump the

used oil or waste on the ground.

Maintenance

Содержание 23316

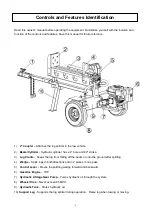

Страница 7: ...7 Component Parts...

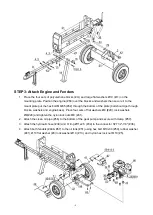

Страница 20: ...20 Parts Drawing Parts List...