- 11 -

STEP 6:

Add Hydraulic Oil

1. The log splitter needs to be on a flat, level surface before adding the hydraulic oil.

2. Remove the oil cap from the hydraulic oil tank.

3. Add approximately 2.64 gallons (10L) of hydraulic oil AW32, AW46 & universal hydraulic oil are

all acceptable types of fluid.

Automatic transmission fluid should be used when operating in

temperatures below 32 degrees

(all units are tested and have excess oil in the ram).

4. Check the hydraulic oil level.

5. Start engine and use the control lever to extend and retract wedge several times to remove air

from the lines.

6. With the wedge retracted, check hydraulic oil level again and fill if necessary.

Note: For extended use with outdoor temperatures above 70ºF it is recommend DEXTRON III.

WARNING

DO NOT remove the hydraulic oil fill cap when the engine is running or hot. Hot oil can escape

causing severe burns. Always allow the log splitter to cool completely before removing the hydraulic

oil cap.

Always

stop the engine, disconnect the spark plug, and move the split control lever back and forth to

relieve pressure before changing or adjusting hydraulic system components; hoses, fittings or other

components.

High fluid pressure and temperatures are created in the hydraulic log splitters. Hydraulic fluid will

escape through a pin-size hole opening and can puncture skin and cause severe blood poisoning.

Inspect hydraulic system regularly for possible leaks.

Never check for leaks with your hand while

the system is pressurized. Seek medical attention immediately if injured by escaping fluid.

Always see a doctor immediately If injured by escaping fluid, no matter how small. An injection injury

may be a small puncture wound that does not look serious but severe infection or reaction can result if

proper medical treatment is not administered immediately by a doctor who is familiar with injection

injuries.

Never adjust the pressure setting of the pump or valve. Make sure all fittings are tight and secure

before applying pressure. Relieve system pressure before servicing.

Make sure the hydraulic hoses do not touch any hot surfaces or cutting areas. Hoses need to be

positioned were they are clear from the engine and cutting wedge. To avoid serious bodily injury

always inspect the hoses before operating the log splitter.

Содержание 23316

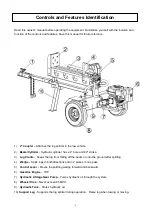

Страница 7: ...7 Component Parts...

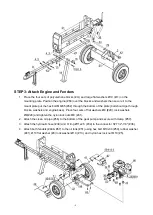

Страница 20: ...20 Parts Drawing Parts List...