JOHNSON CONTROLS

26

FORM 160.69-O2

ISSUE DATE: 9/30/2020

SECTION 2 – SYSTEM OPERATING PROCEDURES

Monthly

Leak check the entire chiller.

Quarterly

Perform chemical analysis of oil.

Semi-Annually (or more often as required)

1.

Change and inspect compressor oil filter element.

2. Oil return system.

a. Change dehydrator.

b. Check nozzle of eductor for foreign particles.

3. Check controls and safety cutouts.

Annually (more often if necessary)

If quarterly inspection indicates oil is fine,

replacing the oil is not necessary.

1. Drain and replace the oil in the compressor oil

sump. (See “Oil Charging Procedure”)

2. Evaporator and Condenser.

a. Inspect and clean water strainers.

b. Inspect and clean tubes as required.

c. Inspect end sheets.

3. Compressor Drive Motor (See motor manufactur-

ers maintenance and service instruction supplied

with unit)

a. Clean air passages and windings per manu-

facturers instructions.

b. Meg motor windings – See

Figure 11 on

page 26

for details.

c. Lubricate per motor manufacturer recom-

mendations.

4. Inspect and service electrical components as neces-

sary.

5. Perform refrigerant analysis.

OPERATING INSPECTIONS

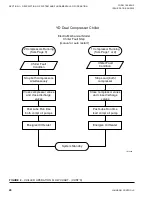

By following a regular inspection using the display

readings of the Microcomputer Control Center, and

maintenance procedure, the operator will avoid serious

operating difficulty. The following list of inspections

and procedures should be used as a guide.

Daily

1. Check OptiView™ Control Center displays.

2. If the compressor is in operation, check the bear-

ing oil pressure on the

SYSTEM

Screen. Also

check the oil level in the oil reservoir. Operating

oil level should be operating range of oil indicator.

Drain or add oil if necessary.

3. Check entering and leaving condenser water pres-

sure and temperatures for comparison with job

design conditions. Condenser water temperatures

can be checked on the

SYSTEM

Screen.

4. Check the entering and leaving chilled liquid tem-

peratures and evaporator pressure for compari-

son with job design conditions on the

SYSTEM

Screen.

5. Check the condenser saturation temperature

(based upon condenser pressure sensed by the

condenser transducer) on the

SYSTEM

Screen.

6. Check the compressor discharge temperature on

the

SYSTEM

Screen. During normal operation

discharge temperature should not exceed 220°F

(104°C).

7. Check the compressor motor current on the

SYS-

TEM

Screen.

8. Check for any signs of dirty or fouled condenser

tubes. (The temperature difference between water

leaving condenser and saturated condensing tem-

perature should not exceed the difference record

-

ed for a new unit by more than 4°F, 2.2°C).

Weekly

Check the refrigerant charge. (See

Содержание YD A

Страница 8: ...JOHNSON CONTROLS 8 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 22: ...JOHNSON CONTROLS 22 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 28: ...JOHNSON CONTROLS 28 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 34: ...JOHNSON CONTROLS 34 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 48: ...JOHNSON CONTROLS 48 FORM 160 69 O2 ISSUE DATE 9 30 2020 THIS PAGE INTENTIONALLY LEFT BLANK...