5532522-UIM-B-0619

2

Johnson Controls Ducted Systems

7. Always install the furnace to operate within the furnace’s intended

temperature rise range. Only connect the furnace to a duct system

which has an external static pressure within the allowable range, as

specified on the furnace rating plate.

8. When a furnace is installed so that supply ducts carry air circulated

by the furnace to areas outside the space containing the furnace,

the return air shall also be handled by duct(s) sealed to the furnace

casing and terminating outside the space containing the furnace.

9. This furnace is not to be used for heating of buildings or structures

under construction.

10. When installed in a non-HUD-Approved Modular Home or building

constructed on-site, combustion air shall not be supplied from occu-

pied spaces.

11. The size of the unit should be based on an acceptable heat loss

calculation for the structure. ACCA, Manual J or other approved

methods may be used.

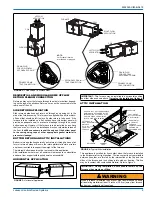

12. When moving or handling this furnace prior to installation it is rec-

ommended to leave the doors on the furnace to provide support

and to prevent damage or warping of the cabinet. When lifting the

furnace by the cabinet, support the ends of the furnace rather than

lifting by the cabinet flanges at the return air openings (bottom or

sides) or supply air opening.

13. When lifting the furnace, it is acceptable to use the primary heat

exchanger tubes as a lifting point provided that the tubes are lifted

at the front of the heat exchangers where attached to the vestibule

panel. Do not use the top return bend of the heat exchangers as lift-

ing points as the tubes may shift out of position or their location

brackets/baffles.

SAFETY REQUIREMENTS

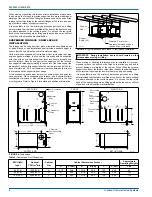

• Refer to the unit rating plate for the furnace model number, and

then see the dimensions page of this instruction for return air ple-

num dimensions in Figure 6. The plenum must be installed

according to the instructions.

• Provide clearances from combustible materials as listed under

Clearances to Combustibles.

• Provide clearances for servicing ensuring that service access is

allowed for both the burners and blower.

• These models

ARE NOT

CSA listed or approved for installation

into a

HUD Approved Modular Home

or a

Manufactured

(Mobile) Home

.

• This furnace is not approved for installation in trailers or recre-

ational vehicles.

• Furnaces for installation on combustible flooring shall not be

installed directly on carpeting, tile or other combustible material

other than wood flooring.

• Check the rating plate and power supply to be sure that the elec-

trical characteristics match. All models use nominal 115 VAC, 1

Phase, 60 Hz power supply. DO NOT CONNECT THIS APPLI-

ANCE TO A 50 Hz POWER SUPPLY OR A VOLTAGE ABOVE

130 VOLTS.

• Furnace shall be installed so the electrical components are pro-

tected from water.

• Installing and servicing heating equipment can be hazardous due

to the electrical components and the gas fired components. Only

trained and qualified personnel should install, repair, or service

gas heating equipment. Untrained service personnel can perform

basic maintenance functions such as cleaning and replacing the

air filters. When working on heating equipment, observe precau-

tions in the manuals and on the labels attached to the unit and

other safety precautions that may apply.

COMBUSTION AIR QUALITY

(LIST OF CONTAMINANTS)

The furnace requires

OUTDOOR AIR

for combustion when the furnace

is located in any of the following environments.

• Restricted Environments

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces installed in hobby or craft rooms

• Furnaces installed near chemical storage areas

• Chemical exposure

The furnace requires

OUTDOOR AIR

for combustion when the furnace

is located in an area where the furnace is being exposed to the follow-

ing substances and / or chemicals.

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

When outdoor air is used for combustion, the combustion air intake duct

system termination must be located external to the building and in an

area where there will be no exposure to the substances listed above.

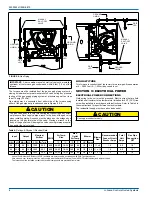

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result in serious

injury, death or property damage.

Never test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for detection of leaks to

check all connections. A fire or explosion may result causing property

damage, personal injury or loss of life.

IMPORTANT: During installation, doors should remain on the

furnace when moving or lifting.

CAUTION

This product must be installed in strict compliance with the installation

instructions and any applicable local, state, and national codes

including, but not limited to building, electrical, and mechanical codes.

!

!

WARNING

The furnace area must not be used as a broom closet or for any other

storage purposes, as a fire hazard may be created. Never store items

such as the following on, near or in contact with the furnace.

1. Spray or aerosol cans, rags, brooms, dust mops, vacuum clean-

ers or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning compounds;

plastic items or containers; gasoline, kerosene, cigarette lighter

fluid, dry cleaning fluids or other volatile fluid.

3. Paint thinners and other painting compounds.

4. Paper bags, boxes or other paper products

Never operate the furnace with the blower door removed. To do

so could result in serious personal injury and/or equipment

damage.

!