5532522-UIM-B-0619

20

Johnson Controls Ducted Systems

gle call for heat, the control will also indicate 4 Red Flashes and will

enter a one-hour soft lockout.

5 RED FLASHES:

Flame present with gas valve off. This fault indicates

that the control board has sensed a flame during a period when the gas

valve is not supposed to be open. Check for miswiring. The control will

enter a hard lockout and power will have to be cycled off and on to reset

the control after the problem has been corrected.

6 RED FLASHES:

Auxiliary limit switch open. This indicates that the

limit switch mounted on the burner box is open, indicating an overheat-

ing condition in the burner. Check for a blocked vent or an overfired

condition.

7 RED FLASHES:

Gas valve short circuit. This fault code indicates that

the control board has sensed that the gas valve circuit is shorted.

Check for miswiring of the gas valve or a shorted gas valve wire.

1 AMBER FLASH:

Low flame current. Indicates that the flame current

being sensed by the flame sensor has dropped below the normal level.

The furnace will continue to operate in this condition, but if the flame

current continues to drop, the burners will shut down. Check for a dirty

or bent flame sensor.

2 AMBER FLASHES:

ID Plug Failure. This furnace is equipped with an

ID plug on the control board that is used to transmit model-specific

information to the board. If this error occurs, it means that the control is

unable to detect the ID plug. The furnace will not operate properly with-

out the correct ID plug being installed.

3 AMBER FLASHES:

Control fuse open.

This indicates that the low

voltage fuse on the control board has opened or is missing.

RAPID RED FLASHES:

Incorrect line voltage polarity.

The polarity of

the incoming power to the furnace is reversed.

SOFT LOCKOUT:

This control includes a soft lockout that will reset

automatically after one hour. This provides protection to an unoccupied

structure if a temporary condition exists causing a furnace malfunction.

An example of this is a temporary interruption in gas supply that would

prevent the furnace from lighting. The control will keep trying to light

each hour and will resume normal operation if the gas supply is

restored.

HARD LOCKOUT:

Some fault conditions result in a hard lockout, which

requires power to the control to be turned off and then back on to reset

the control. The control will not automatically restart.

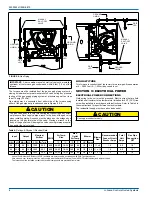

DIAGNOSTIC FAULT CODE STORAGE AND

RETRIEVAL

The control in this furnace is equipped with memory that will store up to

five error codes to allow a service technician to diagnose problems

more easily. This memory will be retained even if power to the furnace

is lost.

This feature should only be used by a qualified service tech-

nician.

If more than five error codes have occurred since the last reset, only the

five most recent will be retained. The furnace control board has a but-

ton, labeled “LAST ERROR” that is used to retrieve error codes. This

function will only work if there are no active thermostat signals. So any

call for heating, cooling or continuous fan must be terminated before

attempting to retrieve error codes.

To retrieve the error codes, push the LAST ERROR button. The LED on

the control will then flash the error codes that are in memory, starting

with the most recent. There will be a two-second pause between each

flash code. After the error codes have all been displayed, the LED will

resume the normal slow green flash after a five second pause. To

repeat the series of error codes, push the button again.

If there are no error codes in memory, the LED will flash two green

flashes. To clear the memory, push the LAST ERROR button and hold it

for more than five seconds. The LED will flash three green flashes when

the memory has been cleared, then will resume the normal slow green

flash after a five-second pause.

IGNITION CONTROL FLAME SENSE LEVELS

Normal flame sense current is approximately

3.7 microamps DC (

μ

a)

Low flame signal warning starts at 1.5 microamps.

Low flame signal control lockout point is

0.1 microamps DC (

μ

a)