FORM 160.55-O1 (604)

7

YORK INTERNATIONAL

combination Logic/Trigger Board that interfaces the

Con trol Center with a serial communications link. Ear-

li er vintage chillers, such as those encountered in Con trol

Cen ter retro

Þ

t ap pli ca tions are equipped with the Mod

“A” starter. This Start er con tains a Trig ger Board that

in ter fac es to a Logic Board that is in stalled inside of the

Control Cen ter.

In operation, a liquid (water or brine to be chilled)

ß

ows

through the cooler, where boiling refrigerant absorbs heat

from the liquid. The chilled liquid is then piped to fan

coil units or other air conditioning terminal units, where

it

ß

ows through

Þ

nned coils, absorbing heat from the

air. The warmed liquid is then returned to the chiller to

complete the chilled liquid circuit.

The refrigerant vapor, which is produced by the boil ing

action in the cooler,

ß

ows to the compressor where the

rotating impeller increases its pressure and tem per a ture

and discharges it into the condenser. Water

ß

ow ing

through the condenser tubes absorbs heat from the re frig -

er ant va por, causing it to condense. The con dens er water

is sup plied to the chiller from an external source, usually

a cool ing tower. The condensed re frig er ant drains from

the con dens er into the liquid return line, where the vari-

SECTION 1

DESCRIPTION OF SYSTEM AND FUNDAMENTALS OF OPERATION

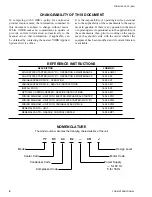

29509A

CONDENSER

CONTROL

CENTER

COMPRESSOR

MOTOR

COOLER

FIG. 1 –

MODEL YT MILLENNIUM CHILLER

SYSTEM OPERATION DESCRIPTION (SEE FIG. 2)

The YORK Model YT Millennium Chiller is commonly

ap plied to large air conditioning systems, but may be

used on other applications. The chiller consists of an

open motor mounted to a compressor (with integral

speed in creas ing gears) condenser, cooler and vari able

ß

ow con trol.

The chiller is controlled by a modern state of the art

OptiView Control Center that monitors its op er a tion. The

Control Center is programmed by the op er a tor to suit job

speci

Þ

cations. Automatic timed start-ups and shut downs

are also programmable to suit night time, week ends and

holidays. The operating status, tem per a tures, pressures

and other information per ti nent to op er a tion of the chiller

are automatically dis played and read on a graphic mes-

sage display. Other displays can be ob served by press ing

the keys as labeled on the Con trol Center. The chill er

with the OptiView Control Cen ter is applied with an

electro-mechanical start er, YORK Solid State Start er

(optional) or Variable Speed Drive (optional).

There could be either of two different Solid State Start-

ers applied. New production chillers are equipped with

the Mod “B” Solid State Starter. This starter contains a

1

PURGE

UNIT

Содержание R123

Страница 2: ...YORK INTERNATIONAL 2 FORM 160 55 O1 604...

Страница 11: ...FORM 160 55 O1 604 11 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT...

Страница 35: ...FORM 160 55 O1 604 35 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 37: ...FORM 160 55 O1 604 37 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 63: ...FORM 160 55 O1 604 63 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 67: ...FORM 160 55 O1 604 67 YORK INTERNATIONAL 2 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT...

Страница 73: ...FORM 160 55 O1 604 73 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 111: ...FORM 160 55 O1 604 111 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 136: ...YORK INTERNATIONAL 136 FORM 160 55 O1 604 Operational Maintenance LD00470 FIG 61 ASSEMBLY OF DEHYDRATOR...

Страница 155: ...FORM 160 55 O1 604 155 YORK INTERNATIONAL NOTES...