YORK INTERNATIONAL

130

FORM 160.55-O1 (604)

System Op er at ing Pro ce dures

con dens er wa ter, and cool ing tower fans will stop

au to mat i cal ly. The oil pump will continue to run

for a pe ri od of 150 sec onds. The oil pump will then

stop au to mat i cal ly. Once stopped, the

“SYS TEM

COASTDOWN”

display will be re placed by

“SYS-

TEM READY TO START”.

2. Stop the chilled water pump (if not wired into the

OptiView Control Center, in which case it will

shut off au to mat i cal ly si mul ta neous ly with the oil

pump.) (The actual water pump contact op er a tion is

de pen dent upon the po si tion of Microboard Program

Switch SW1-8.)

3. Open the switch to the cooling tower fan mo tors, if

used.

4. The com pres sor sump oil heat er (ther mo stat i cal ly

controlled) is en er gized when the unit is stopped.

PROLONGED SHUTDOWN

If the chiller is to be shut down for an extended period of

time (for example, over the winter season), the fol low ing

paragraphs outline the procedure to be fol lowed.

1. After the system pressure has risen above at mo -

spher ic, test all system joints for refrigerant leaks

with a leak detector. If equipment room is below

70°F, circulate hot water (not to exceed 100°F)

through the cooler tubes to raise the system pres-

sure. If any leaks are found, they should be repaired

before al low ing the system to stand for a long pe ri od

of time.

During long idle periods, the tightness of the sys tem

should be checked periodically.

2. If freezing temperatures are encountered while the

system is idle, carefully drain the cooling water from

the cooling tower, condenser, condenser pump, and

the chilled water system-chilled water pump and

coils. Open the drains on the cool er and con dens er

liq uid heads to assure com plete drain age. (If a Vari-

able Speed Drive, drain its water cool ing system. If

Sol id State Start er, drain water from start er cooling

loop. Isolate the Turboguard purge unit from the

main sys tem.)

3. Isolate the Turboguard purge unit from the main

sys tem.

4. Disable clock on

SETUP

Screen. This con serves the

bat tery.

5. Open the main dis con nect switches to the com pres sor

motor, con dens er water pump and the chilled water

pump. Open the 115 volt circuit to the Con trol Cen-

ter.

START UP AFTER PRO LONGED SHUT DOWN

1. When put ting the system into op er a tion after pro-

longed shut down (during the win ter), re move all

oil from the com pres sor. Install a new

Þ

lter element

and charge com pres sor with fresh oil. Re place purge

unit and oil re turn

Þ

lters. Enable clock on

SETUP

Screen.

2. Operate the “

OIL PUMP

” (press and re lease the

man u al oil pump key) un til steady oil pressure is es-

tab lished. Then press and release the “

OIL PUMP

”

key to stop operation of the oil pump. If the water

sys tems were drained,

Þ

ll the con dens er water cir cuit

and chilled liquid circuit.

Содержание R123

Страница 2: ...YORK INTERNATIONAL 2 FORM 160 55 O1 604...

Страница 11: ...FORM 160 55 O1 604 11 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT...

Страница 35: ...FORM 160 55 O1 604 35 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 37: ...FORM 160 55 O1 604 37 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 63: ...FORM 160 55 O1 604 63 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 67: ...FORM 160 55 O1 604 67 YORK INTERNATIONAL 2 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT...

Страница 73: ...FORM 160 55 O1 604 73 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 111: ...FORM 160 55 O1 604 111 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

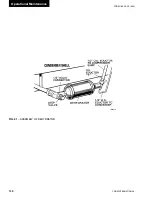

Страница 136: ...YORK INTERNATIONAL 136 FORM 160 55 O1 604 Operational Maintenance LD00470 FIG 61 ASSEMBLY OF DEHYDRATOR...

Страница 155: ...FORM 160 55 O1 604 155 YORK INTERNATIONAL NOTES...