YORK INTERNATIONAL

148

FORM 160.55-O1 (604)

CHECKING THE REFRIGERANT CHARGE DURING UNIT SHUT DOWN

HANDLING REFRIGERANT FOR

DISMANTLING AND REPAIRS

The refrigerant charge is speci

Þ

ed for each chiller mod el

(See Table 4). Charge the cor rect amount of re frig er ant

and record the level in the cooler sight glass.

The re frig er ant charge should al ways be checked and

trimmed when the system is shut down.

The refrigerant charge level must be checked after the

pressure and tem per a ture has equalized between the

con dens er and cooler. This would be expected to be 4

hours or more after the com pres sor and water pumps are

stopped. The level should be at the center of the sight

glass ±1/4 inch.

Charge the refrigerant in ac cor dance with the method

shown under “Refrigerant Charging” above. The re frig -

er ant lev el should be observed and the level re cord ed

af ter initial charg ing.

If it becomes necessary to open any part of the re frig er ant

system for repairs, the fol low ing para graphs out line the

procedure for handling the re frig er ant while the sys tem

is open.

Since Re frig er ant-123 boils at 82°F under at mo spher ic

pressure, it will not be necessary to remove the re frig -

er ant if the system it to be open for only a few hours. Any

part of the system which is above the liquid level will be

ac ces si ble without disturbing the re frig er ant charge.

If the system must re main open for more than a few

hours the refrigerant should be drained and stored in

clean drums for the duration of the repair pe ri od.

If con di tions permit, the system pressure should be as

near as possible to at mo spher ic before opening the sys-

tem and the re frig er ant charge should be kept as near

as possible to 82°F to keep ei ther the re frig er ant loss or

the air intake to a min i mum. After the system has been

re-as sem bled, the air should be removed by means of

the purge unit. (See “Purging the System”.)

MEGGING THE MOTOR

While the main disconnect switch and compressor mo tor

starter are open, meg the motor as follows:

1. Using a megohm meter (megger), meg between

phas es and each phase to ground (see Fig. 65); these

readings are to be interpreted using the graph shown

in Fig. 66.

2. If readings fall below shaded area, remove ex ter nal

leads from motor and repeat test.

Motor is to be megged with the starter

at ambient temperature after 24 hours

of idle stand by.

Maintenance

Содержание R123

Страница 2: ...YORK INTERNATIONAL 2 FORM 160 55 O1 604...

Страница 11: ...FORM 160 55 O1 604 11 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT...

Страница 35: ...FORM 160 55 O1 604 35 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 37: ...FORM 160 55 O1 604 37 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 63: ...FORM 160 55 O1 604 63 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 67: ...FORM 160 55 O1 604 67 YORK INTERNATIONAL 2 THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT...

Страница 73: ...FORM 160 55 O1 604 73 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

Страница 111: ...FORM 160 55 O1 604 111 YORK INTERNATIONAL THIS PAGE INTENTIONALLY LEFT BLANK TO MAINTAIN FORMAT 2...

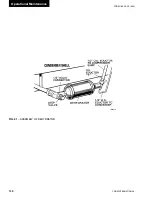

Страница 136: ...YORK INTERNATIONAL 136 FORM 160 55 O1 604 Operational Maintenance LD00470 FIG 61 ASSEMBLY OF DEHYDRATOR...

Страница 155: ...FORM 160 55 O1 604 155 YORK INTERNATIONAL NOTES...