Upflow furnaces may be installed horizontally with the supply

airflow toward the left or right by laying the unit on the left or

right panel. Do not install the unit on the rear panel.. After

determining the best orientation, lay the unit on top of the

shipping carton to protect the finish.

The appropriate electrical knock-outs for power wiring, control

wiring and gas piping should be removed at this time.

When in the horizontal position, return air may enter through

the end of the unit, the bottom panel, the top panel or any

combination of these openings. Return air may not be con-

nected into the rear panel of the unit.

To convert the upflow model furnace to open bottom, refer to

the Upflow Application - Bottom Return section of this manual

and follow steps 1 thru 4 to remove the bottom closure panel.

ATTIC INSTALLATION

This appliance is design certified for line contact for furnaces

installed horizontally. The intersection of the furnace top and

sides form a line.

This line may be in contact with combustible material. However,

refer to "Venting" and "Clearances" in this manual for additional

information.

Secure a platform constructed of plywood or other building

material to the floor joists. Sheet metal, 12" in front of the

furnace is required. Refer to Figure 6 for details.

WARNING: When a furnace is installed in an attic or other

insulated space, keep all insulating materials at least 12"

away from furnace and burner combustion air openings.

CRAWL SPACE INSTALLATION

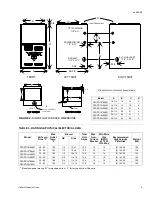

The furnace can be hung from floor hoists or installed on suitable

blocks or pad. Blocks or pad installations shall provide adequate

height to ensure the unit will not be subject to water damage.

When suspending the furnace from rafters or floor joists using

rod, pipe or straps, refer to Physical Data (Page 4) for furnace

weights to determine suitable means of suspension. Angle

supports should be placed at the supply air end and near the

blower deck. Units may also be suspended by using straps or

other material at the same location. All four suspension points

must be level to ensure quiet furnace operation.

1/4"

SUPPORT

ROD

ANGLE IRON

BRACKET

6" MIN BETWEEN

ROD & FURNACE

MIN. 1' CLEARANCE

BETWEEN FURNACE

TOP & COMBUSTIBLES

1" MAX BETWEEN

ROD & FURNACE

1" MAX BETWEEN

ROD & FURNACE

IA

MON

80

D

D

IA

MON

80

D

D

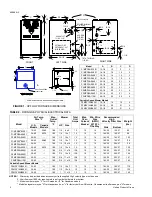

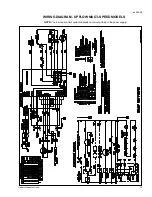

UPFLOW/HORIZONTAL MODELS

VENT (MAINTAIN

REQUIRED CLEARANCES

TO COMBUSTIBLES)

GAS PIPING

SEDIMENT TRAP

12"

30" MIN

WORK AREA

SHEET METAL

IN FRONT

OF FURNACE

RETURN AIR

SUPPLY AIR

LINE CONTACT ONLY PERMISSIBLE

BETWEEN LINES FORMED BY THE

INTERSECTION OF FURNACE TOP

AND TWO SIDES AND BUILDING

JOISTS, STUDS OR FRAMING

FIGURE 6 - TYPICAL ATTIC INSTALLATION

FIGURE 7 - TYPICAL FURNACE INSTALLATION

USING SUSPENSION MATERIALS

HORIZONTAL APPLICATION - P2MP MODELS ONLY

2. Remove the four screws securing the front bottom angle and

remove it from the unit. Keep the angle for reinstallation.

3. Remove the screws from the furnace wrapper which secure

the bottom closure panel and remove the panel from the

blower compartment by pulling it forward and tilting upward.

4. Reinstall the front bottom angle and access doors.

Bottom return applications normally pull return air through a

base platform or return air plenum. Refer to Figure 5 for opening

dimensions. Be sure the return platform structure is suitable to

support the weight of the furnace. Seal the furnace to the

plenum to prevent air leakage.

NOTE: If an external mounted filter rack is being used, see the

instructions provided with that accessory for proper hole

cut size.

Upflow attic installations must meet all minimum clearances to

combustibles and have floor support with required service

accessibility.

650.69-N3

8

Unitary Products Group

Содержание P2DP Series

Страница 23: ...NOTES 650 69 N3 Unitary Products Group 23 ...