The recommended source of combustion air is to use the

outdoor air supply. Excessive exposure to contaminated com-

bustion air will result in safety and performance related prob-

lems. However, the use of indoor air in most applications is

acceptable, except as follows:

1. If the furnace is installed in a confined space it is recommended

that the necessary combustion air come from the outdoors by

way of attic, crawl space, air duct or direct opening.

2. If outdoor combustion air is used, there must be no expo-

sure to the installations or substances listed in "3" below.

3. The following types of installations may require OUT-

DOOR AIR for combustion, due to chemical exposure.

a)

Commercial buildings

b)

Buildings with indoor pools

c)

Furnaces installed in laundry rooms

d)

Furnaces installed in hobby or craft rooms

e)

Furnaces installed near chemical storage areas

Exposure to the following substances in the combustion air

supply may also require OUTDOOR AIR for combustion.

f)

Permanent wave solutions

g)

Chorinated waxes and cleaners

h)

Chorine based swimming pool chemicals

i)

Water softening chemicals

j)

De-icing salts or chemicals

k)

Carbon tetrachloride

l)

Halogen type refrigerants

m) Cleaning solvents (such as perchloroethylene)

n)

Printing inks, paint removers, varnishes, etc.

o)

Hydrochloric acids

p)

Cements and glues

q)

Antistatic fabric softeners for clothes dryers

r)

Masonry acid washing chemicals

VENTING

CATEGORY I VENTING

Category I venting consists of vertically venting one or more

appliances in B-vent or masonry chimney (as allowed), using

single wall metal pipe or B-vent connectors.

NOTE: This appliance may be common vented with another gas

appliance as allowed by the following codes and standards.

The furnace rating plate lists the maximum vent gas temperature.

This temperature must be used used to select appropriate venting

materials and clearances. A typical example is shown below.

"CATEGORY 1/450

°

F. MAX. VENT TEMP."

All installations must be vented in accordance with the National

Fuel Gas Code, NFPA 54/ANSI Z223.1 - latest edition. For

reference, the National Fuel Gas Code Handbook, available

from NFPA (item JP-54HB92) is recommended. The appliance

must also be vented in compliance with all local utility and code

requirements. In Canada, the furnace must be vented in

accordance with the National Standard of Canada, CAN/CGA-

B149.1 and .2 - latest editions.

WARNING: A furnace shall not be connected to a chimney flue

serving a separate appliance designed to burn solid fuel.

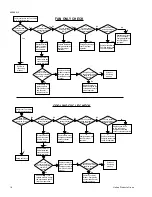

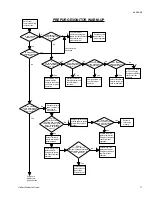

VENT SAFETY CHECK PROCEDURE

WARNING: If this furnace is replacing a common-vented fur-

nace, it may be necessary to resize the existing vent line

and chimney to prevent oversizing problems for the new

combination of units. Refer to the National Fuel Gas Code,

ANSI Z223.1 or CAN/CGA B149.1 or .2 Installation Code

- latest editions.

The following steps shall be followed with each appliance

connected to the venting system placed in operation, while any

other appliances connected to the common venting system are

not in operation.

1. Seal any unused openings in the common venting system.

2. Inspect venting system for proper size and horizontal pitch,

as required in the National Fuel Gas Code ANSI Z223.1

or the CAN/CGA B149 Installation Codes and these in-

structions. Determine that there is no blockage or restric-

tion, leakage, corrosion or other deficiencies which could

cause an unsafe condition.

3. Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliance(s)

connected to the venting system are located and other

spaces of the building. Turn on clothes dryers and any

other appliances not connected to the common venting

system. Turn on any clothes dryers and any appliance not

connected to the venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts so they

will operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Place the appliance being

operated in operation. Adjust thermostat so appliance will

operate continuously.

5. Test for draft hood equipped appliance spillage at the draft

hood relief opening after 5 minutes of main burner opera-

tion. Use the flame of a match or candle.

6. After it has been determined that each appliance connected

to the venting system properly vents when tested as outlined

above, return doors, windows, exhaust fans, fireplace damp-

ers and any other gas-burning appliance to their previously

conditions of use.

7. If improper venting is observed during any of the above

tests, the venting system must be corrected.

8. Any corrections or resizing of the common venting system

must be in accordance with the National Fuel Gas Code,

ANSI Z223.1 or Section 7, Venting Systems and Air Supply

for Appliances, CAN/CGA B149.1 or .2 Installation Code -

latest editions. If the common vent system must be resized,

it should be resized to approach the minimum size as deter-

mined using the appropriate tables in Appendix G of the

above codes or the venting tables supplied with the furnace.

DUCTWORK

The duct system’s design and installation must:

1. Handle an air volume appropriate for the served space and

within the operating parameters of the furnace specifications.

2. Be installed in accordance with standards of NFPA

(National Fire Protection Association) as outlined in

NFPA pamphlets 90A and 90B ( - latest editions).

3. Create a closed duct system. The supply system must be

connected to the furnace outlet and the return duct system

must be connected to the furnace inlet. Both supply and

return duct systems must terminate outside the space

containing the furnace.

4. Generally complete a path for heated or cooled air to

circulate through the air conditioning and heating equip-

ment and to and from the conditioned space.

CAUTION: The cooling coil must be installed in the supply air

duct downstream of the furnace.

When the furnace is used in conjunction with a cooling coil, the

furnace must be installed parallel with, or on the upstream side of the

cooling unit to avoid condensation in the primary heat exchanger.

When a parallel flow arrangement is used, the dampers or other

means used to control air flow must be adequate to prevent

chilled air from entering the furnace, and if manually operated,

must be equipped with means to prevent operating of either

unit unless the damper is in the full heat or cool position.

WARNING

It is the responsibility of the installer to verify proper vent

system operation.

650.69-N3

6

Unitary Products Group

Содержание P2DP Series

Страница 23: ...NOTES 650 69 N3 Unitary Products Group 23 ...