035-15241-003 Rev. A (201)

Unitary Products Group

9

2.

If two duct systems are used as could be the case with a

coil-blower or a self-contained A/C unit, the furnace and

A/C unit should be controlled by a single combination

heating and cooling thermostat which will prevent the fur-

nace and A/C unit from operating simultaneously.

RETURN AIR AND FILTERS

RETURN AIR TEMPERATURE

This furnace design is to be operated in normal household

temperatures. The continuous return air temperature must

not be below 60°F or above 85°F.

RETURN AIR CONNECTION - UPFLOW

The return air may be brought in through the bottom of the

furnace or through one or both sides of the furnace casing.

The furnace casing may be cut out so that side return air con-

nections may be used. The furnace is supplied with flanges

on the top of the furnace to which the return air duct may be

fastened. The casing top is embossed to indicate where to

bend the flanges. If a side return is to be used, cut out the

side of the casing 14" high by 16 1/4" wide using the lances in

the casing side as a guide.

DO NOT CUT THE OPENING

LARGER THAN 14"x 16 1/4".

It is not permissible to cut out

the back of the furnace.

The return air ducts to the furnace must have a total cross

sectional area of not less than two square inches per 1000

BTUH of furnace input rating for heating operation. If air con-

ditioning is to be installed with the furnace, or if it may be

added at a later time, larger return air ducts may be required,

depending on the capacity of the air conditioner and the air-

flow required. For applications requiring more than 1800

CFM, it will be necessary to use the bottom return, both side

returns or one side plus the bottom return.

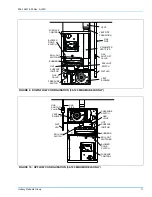

RETURN AIR CONNECTION - DOWNFLOW

(50-125 MBH MODELS ONLY)

The return air connection to the furnace must be attached to

the top of the furnace. It is not permissible to cut out the side

of the furnace casing for side return ducts. The furnace is

supplied with flanges on the top of the furnace to which the

return air duct may be fastened. The casing top is embossed

to indicate where to bend the flanges.

The return air ducts to the furnace must have a total cross

sectional area of not less than two square inches per 1000

BTUH of furnace input rating for heating operation. If air con-

ditioning is to be installed with the furnace, or if it may be

added at a later time, larger return air ducts may be required,

depending on the capacity of the air conditioner and the air-

flow required. The return air opening in the top of the furnace

is large enough for the largest capacity air conditioner for

which the furnace blower is rated.

RETURN AIR CONNECTION - HORIZONTAL

The return air duct must be connected to the inlet end of the

furnace. It is not permissible to cut out the side of the furnace

casing for side return ducts. The furnace is supplied with

flanges on both ends of the furnace to which the supply and

return air ducts may be fastened. The casing is embossed on

both ends to indicate where to bend the flanges.

The return air ducts to the furnace must have a total cross

sectional area of not less than two square inches per 1000

BTUH of furnace input rating for heating operation. If air con-

ditioning is to be installed with the furnace, or if it may be

added at a later time, larger return air ducts may be required,

depending on the capacity of the air conditioner and the air-

flow required. The return air opening in the top of the furnace

is large enough for the largest capacity air conditioner for

which the furnace blower is rated.

FILTERS

Air filters must be used with this furnace. Failure to do so will

cause dirt to accumulate on the furnace blower motor, blower

wheel, heat exchanger and air conditioning coil, resulting in

reduced system efficiency, erratic control performance and

possible equipment damage.

Air velocity must not exceed 300 feet per minute through low

velocity disposable filters. Air velocity must not exceed 650

feet per minute through high velocity cleanable permanent fil-

ters. Use of a filter that is too small will cause static pressure

in the duct system to be too high, which will have an adverse

effect on heating and cooling operation.

If a separate heating and separate cooling ther-

mostat is used, a manually operated electrical in-

terlock switch must be installed to prevent

simultaneous operation of both systems and to

avoid a possible hazardous condition due to

overheating of the conditioned space.

When side return air ducts are used, a solid metal

block-off panel must be used to block the bottom

opening in the furnace. Failure to do so could

cause flue gases to be drawn into the living

space, which could result in asphyxiation.

When the furnace is installed so that supply ducts

carry air circulated by the furnace to areas out-

side the space containing the furnace, the return

air must also be handled by a duct(s) sealed to

the furnace casing and terminating outside the

space containing the furnace. Failure to do so

can result in asphyxiation.