035-15241-003 Rev. A (201)

22

Unitary Products Group

2.

Place thermometer in return air duct about two feet from

furnace, with the tip of the thermometer as near as possi-

ble to the center of the duct.

3.

Set thermostat to highest temperature setting and allow

furnace to run for at least five minutes before checking

temperatures.

4.

Calculate air temperature rise by subtracting supply air

temperature from the return air temperature.

5.

If temperature rise is not within the range shown on the

furnace rating plate, the blower speed may need to be

changed.

6.

If the blower speed is changed, recheck the temperature

rise by repeating steps 1 through 4 above.

7.

If the air temperature rise is not within the proper range

even after changing blower speeds, check ductwork

design with a qualified heating engineer. It may be nec-

essary to re-size the ductwork.

BALANCE THE SYSTEM

The air distribution system should be balanced, using in-line

duct dampers if employed, to provide for satisfactory air deliv-

ery to room. It is recommended that dampers in registers not

be used for balancing the system.

SERVICE INSTRUCTIONS

MOTOR LUBRICATION

The circulating air blower motor and vent blower are perma-

nently lubricated and do not require periodic lubrication.

BURNER CLEANING

The burners used in this furnace are specially designed to be

non-linting and should not require periodic cleaning. In the

event that cleaning does become necessary, use the suction

hose of a suitable vacuum cleaner to remove dirt and lint. Be

careful not to damage the ignitor or sensor rod during clean-

ing.

FLUE GAS PASSAGEWAYS

Periodic cleaning of the heat exchanger and flue gas pas-

sageways is not necessary and is not recommended under

normal circumstances.

REPLACEMENT PARTS

Should it be necessary to replace any component parts,

these may be obtained through an authorized dealer, who is

experienced and can be of assistance. Information on the

nearest Distributor may be obtained directly from the com-

pany shown on the furnace rating plate.

Following major service or replacement of functional parts, it

is recommended that the furnace be operated in the various

modes to insure that performance is normal and control com-

ponents are functioning properly.

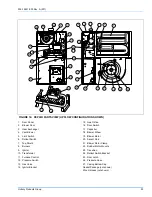

The parts listed below are only those that are functional parts

and those that might require replacement. The parts listed

are by part name (description) only and CODE reference

NUMBER. The CODE number is used to determine the loca-

tion of the part in the generalized, pictorial illustration pro-

vided. See Figure 16.

When ordering parts - order by name and description. Do not

order by code number. Also when ordering parts please pro-

vide:

1.

Complete furnace Model Number and Serial Number.

These may be found on the rating plate located behind

the front panel (door) of the furnace.

2.

Type of gas being used.

3.

Is furnace being used in conjunction with air conditioning

or heat pump?

Never attempt to modify this furnace - fire, explo-

sion, or asphyxiation may result. If malfunction is

apparent, contact a qualified service agency and/

or gas utility for assistance.

Label all wires prior to disconnection when ser-

vicing controls. Wiring errors can cause improper

and dangerous operation.

Verify proper operation after servicing.

Only genuine

Source One

authorized replace-

ment parts should be used. Substitute parts

should not be used, as they may not be the same

in operational and safety characteristics.