035-15241-003 Rev. A (201)

Unitary Products Group

15

3.

Insofar, as is practical, close all building doors and win-

dows and all doors between the space in which the appli-

ances remaining connected to the common venting

system are located and other spaces of the building.

Turn on clothes dryers and any appliance not connected

to the common venting system.

Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at maximum

speed. Do not operate a summer exhaust fan. Close fire-

place dampers.

4.

Follow the lighting instructions. Place the appliance

being inspected in operation. Adjust thermostat so appli-

ance will operate continuously.

5.

Test for spillage at the draft hood relief opening after five

minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar, or

pipe.

6.

After it has been determined that each appliance remain-

ing connected to the common venting system properly

vents when tested as outlined above, return doors, win-

dows, exhaust fans, fireplace dampers, and any other

gas-burning appliance to their previous condition of use.

7.

If improper venting is observed during any of the above

tests, the common venting system must be corrected.

Any changes to the venting system must be in accor-

dance with the National Fuel Gas Code, ANSI Z223.1. In

Canada, any changes to the venting system must be in

accordance with the latest edition of the CAN/CGA-B149

Installation Codes and applicable local codes. If any por-

tion of the common venting system must be resized, it

should be resized to approach the minimum size as

determined using the appropriate tables in Appendix G in

the National Fuel Gas Code, ANSI Z223.1 or in Canada,

the latest edition of the CAN/CGA-B149 Installation

Code.

SIDEWALL VENTING

For applications where vertical Category I venting is not pos-

sible, the only recommended method of sidewall venting is

through the use of an accessory power venter. Only power

venters approved by a nationally recognized approval agency

may be used.

Approved power venters are Tjernlund Models GPAK-JT or

GPAK-1T and Field Controls Models PVG-2 or SWG-4HD.

For installation details, follow the installation instructions sup-

plied with the power venter.

NOTE:

It is recommended that a post-purge timer be used.

This is a device that keeps the power venter in operation for a

short period at the end of each burner cycle in order to clear

out all flue gases from the vent. Manufacturers of power ven-

ters also can supply post-purge timers.

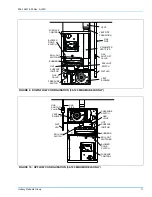

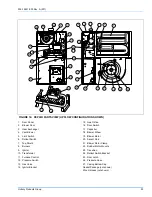

ELECTRICAL WIRING

All internal wiring has been made at the factory. Field wiring

requires only the connection of line voltage supply wiring and

low voltage thermostat wiring.

Service wiring and control wiring may be brought into the fur-

nace through either side using the holes provided.

Refer to the unit rating plate and specification tables found in

these instructions for applicable electrical characteristics and

requirements. A complete wiring diagram is supplied on Page

19.

SERVICE WIRING

Field wiring connections should be made inside the furnace

casing and a suitable strain relief should be used at the point

the wires exit the furnace casing. In order for the electrical

controls in the furnace to operate properly, correct electrical

polarity must be observed. If the furnace does not work on

initial start-up and the diagnostic light on the furnace control

flashes nine times, the polarity is reversed. Field wiring of the

unit should conform to local codes or in the absence of local

codes with the National Electrical Code ANSI/NFPA 70. In

Canada, field wiring of the unit should conform to local codes

or in the absence of local codes with the Canadian Electrical

Code.

A separate fused circuit from the main electrical panel should

serve only the furnace.

ELECTRICAL GROUNDING

The furnace casing must have an uninterrupted electrical

ground in accordance with the National Electrical Code ANSI/

NFPA 70 or, in Canada, with the Canadian Electrical Code,

CSA C22.1. DO NOT use gas piping as an electrical ground.

CONTROL WIRING

The thermostat should be installed in accordance with the

manufacturer's instructions, furnished with the thermostat,

and make connections to the unit as shown on the unit-wiring

diagram. It is recommended that size 18 AWG wire be used.

HEAT ANTICIPATOR

If the wall thermostat has an adjustable heat anticipator, the

setting should be .48 amps. If any accessories are to be con-

nected to the furnace, the heat anticipator setting may

change. Use a suitable ammeter to measure the actual antic-

ipator current.

When sidewall venting these furnaces with a

power venter, it is required that a barometric draft

damper be installed in the vent near the furnace.

Failure to do so could cause a malfunction of the

furnace resulting in asphyxiation.