PAGE 3

11. Locate the two provided adaptor panels, install them in

place of the horizontal access panels removed earlier

using provided #10 x ½" screws.

See Figure 9.

MAXA-MI$ER

Ô

UNITARY ENERGY RECOVERY VENTILATOR

MODEL VR028A15M/H & VR028A25H (STATIONARY)

INSTALLATION

INSTRUCTIONS

5257527-UAI-A-0616 / R28A-18YSDW

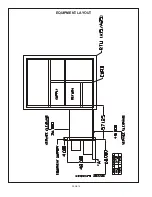

Figure 9

ADAPTOR PANELS

12. Align the provided platform support rail with the center

post of the RTUs return opening. Attach the support

rail to the upper set of pre-drilled holes in the adaptor

panel using the provided #14 screws.

See Figure 10.

PLATFORM SUPPORT RAIL

Figure 10

UERV TOP FILLER PANEL

UNDER RTU TOP

Figure 11

Figure 8

Figure 7

13. Lift the UERV at least 3' (feet), remove the nut and bolt

assembly and slide the telescoping leg out of the

guide. Position the stand off legs so that the foot is on

the bottom of the stand and reinstall the nut and bolt

assembly. Do not tighten nuts at this time as the legs

will have to be adjusted once the unit is finally set in

place

14. Locate provided roll of ¾" x 1 ¼" gasket material. Apply

gasket down the center post of the UERV as well as

between the platform support rail and adaptor panel.

15. Remove screw from the top panel of the RTU in order

to enable lifting the top panel of the RTU up at least 2".

Note: An equipment support or pressure treated

2x6x60" piece of wood should be placed under the

end of the UERV to prevent roof penetration by the

standoff legs.

16. Lift the UERV then move it into position in front of the

horizontal return air adaptor panels.

17. Lower the UERV into place against the RTU, catch the

bottom of the UERV on the platform support rail. With it

in place remove the bolt assembly placed in the

standoff legs in

Step 13

and adjust the legs on the

UERV so that it is level. Insert the bolt assemblies back

into each leg so that the legs are secure and the UERV

sits in a leveled position.

18. Lift the top panel of the RTU enough to slip the top

flange of the UERV under it, lower the top panel over

the flange then reinsert screws.

See Figure 11.

Содержание VR028A15H

Страница 9: ...PAGE 9 ...

Страница 12: ...PAGE 12 EQUIPMENT LAYOUT ...