PAGE 5

During both the summer and winter, the UERV transfers

moisture entirely in the vapor phase. This eliminates wet

surfaces that retain dust and promote fungal growth as well

as the need for a condensate pan and drain to carry water.

Because it is constantly rotating when in the air stream, the

UERV is always being cleared by air, first in one direction

then the other. Because it is always dry, dust or other

particles impinging on the surface during one half cycle,

are readily removed during the next half cycle.

Additional Information for Options are provided in

Options Manual.

Re cov ery Mode

On a thermostat call for blower operation in heating,

cooling or continuous blower, the ERW will rotate between

fresh air and exhaust air streams. Both the fresh air and

exhaust air blowers will also be operating to overcome the

air resistance of the UERV.

Free Cool ing Mode (op tional)

The Start, Stop, Jog kit is an optional control board with

temperature and/or enthalpy sensor(s) that stops the

enthalpy wheel from spinning (and transferring heat) when

temperature conditions are conducive for free cooling.

The board will spin the wheel intermittently in 10 min off 1

min on intervals to keep dust from building up on the

surface.

All units shipped with the Start, Stop, Jog option installed

have the temperature and enthalpy sensors installed, and

the jumper (J9) set to T(emp). A qualified tech can adjust

the setting to E(nthalpy) only or Temp and Enthalpy by

adjusting the jumper (J9).

The factory set points to allow for free cooling during

ventilation are 40

o

F-70

o

F, but they can be field adjusted to

narrow the band by adjusting two potentiometers while

measuring VDC between the Com & High or Com & Low

terminals (0 VDC = 40 degrees, low set point, 5 VDC = 70

degrees, high set point).

IX - Sys tem Check

1.

Disconnect main power.

2.

Turn thermostat to "Cont" for blower operation.

3.

Restore power to unit. Observe UERV wheel rotation

and both fresh air and exhaust air blowers will

operating.

Note: If Low ambient kit is used the jumper between

TB37-5 & TB37-6 should be removed. Also if

system check out is being conducted at low

ambient temperatures, technician should be

aware that this kit can cause system not to

operate.

4.

Verify that the UERV (3) three phase blower motors

are phased sequentially ensuring correct rotation and

operation.

a) Disconnect power.

b) Reverse any two field power leads to the UERV.

c)

Reapply power.

MAXA-MI$ER

Ô

UNITARY ENERGY RECOVERY VENTILATOR

MODEL VR028A15M/H & VR028A25H (STATIONARY)

INSTALLATION

INSTRUCTIONS

5257527-UAI-A-0616 / R28A-18YSDW

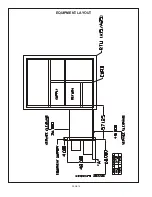

DELTA PRESSURE

Figure 14

A - Return Damper Set tings

Manually adjust position of dampers. This is accomplished

by loosing and tightening set screw on positioning rod.

B - Blower Speed Ad just ment

Blower speed selection is accomplished by changing the

sheave setting on both fresh air and exhaust air blowers.

Both blowers are factory set at "closed" for maximum

airflow. To determine air flow setting, external static

pressure readings will need to be read across the UERV.

See Figure 14

for location to take pressure readings.

C - Air Bal anc ing Ad just ment

1.

Remove plastic plugs in door panels (4 total).

2.

With a manometer measure the pressure drop [Inches

Of water column] across the wheel on the supply

airflow side of the unit (Top). The unit’s CFM is

determined by referring to

Table #1

. If the Cfm value is

not per design adjust the motor sheave until the

desired CFM is reached.

3.

To adjust the exhaust airflow check the pressure on

the exhaust side of the unit (Bottom), then remove the

door panel to access the return air dampers installed

inside the RTUs return air section. Adjustment of the

damper is made by loosening the wingnut, adjusting

the damper blades and then tightening the wingnut

before closing the panel and measuring again.

4.

Once desired the CFM is reached replace the plastic

plugs in the access holes in the doors.

X - Main te nance

Motor Maintenance

All motors use prelubricated sealed bearings; no further

lubrication is necessary.

Mechanical Inspection

Make visual inspection of dampers, linkage assemblies

and UERV rotating bearings during routine maintenance.

Filters should be checked periodically and cleaned when

necessary. Filter is located in fresh air hoods.

DO NOT

replace permanent filters with throwaway type filters.

Содержание VR028A15H

Страница 9: ...PAGE 9 ...

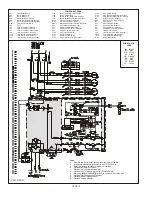

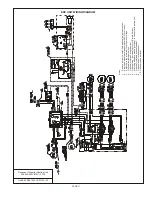

Страница 12: ...PAGE 12 EQUIPMENT LAYOUT ...