9

Fig. 3: Checking Over-Fire Draft.

STACK TEMPERATURE:

Stack temperature will vary depending

on fuel input, circulating air blower

speed, and burner set up, etc. In gen-

eral, stack temperature should typically

range between 380°F to 550°F, assum-

ing that the combustion air is approxi-

mately room temperature (65°F - 70°F).

In general, lower stack temperature indi-

cates greater efficiency; however, ex-

cessively low stack temperature can lead

to condensation forming in the chimney

and / or venting. Sulphur and similar

contaminants in the fuel oil will mix with

condensation to form acids. Acids and

resultant chemical salts will cause rapid

deterioration of the chimney and venting

components, and may attack the fur-

nace.

If the flue gases are below the range, it

may be necessary to slow down the

blower fan. If the flue gases are above

the range, the blower fan may require

speeding up. Stack temperature varies

directly with the system temperature rise.

System temperature rise is the difference

between the furnace outlet temperature

and furnace inlet temperature as meas-

ured in the vicinity of the connection be-

tween the plenum take-offs and the trunk

ducts. Refer to the appliance rating plate

of model for temperature rise range.

If the venting from the furnace to the

chimney is long, or exposed to cold am-

bient temperatures, it may be necessary

to use L-Vent as the vent connector to

reduce stack temperature loss to prevent

condensation. The venting should be

inspected annually to ensure that it is

intact.

FURNACE INSTALLATION SET-

UP

The furnace must be set up as the final

step in the installation.

A) The oil burner must be set up follow-

ing the procedures outlined above.

B) The appliance rating plate should be

consulted for model temperature rise

ranges. To determine the temperature

rise, measure the supply air and return

air temperatures when the furnace has

reached steady state conditions. This is

the point at which the supply air tem-

perature stops increasing relative to the

return air temperature. The furnace may

have to run 10 to 15 minutes to reach

steady state conditions. The measure-

ments may be made with duct ther-

mometers or thermocouples used in con-

junction with multi-meters with tempera-

ture measurement capabilities.

The return air should be measured at a

point where the thermometer will be well

within the air stream near the furnace

return air inlet. Actual location is not par-

ticularly critical; however, avoid locations

where the temperature readings could be

affected by humidifier bypass ducts, the

inside radius of elbows, etc.

The supply air temperature should be

measured at a point where the ther-

mometer will be well within the air stream

near the furnace supply air outlet. Usu-

ally, the side mid-point of the supply air

plenum take-off is ideal, providing it is

out of the line of sight to the heat ex-

changer. If the thermometer is within the

line of sight of the heat exchanger, the

supply air readings may be skewed by

radiant heat from the heat exchanger. If

the plenum take-off is unsuitable, the

supply air temperature may be measured

within the first 18 inches of the first seg-

ment of supply air trunk duct.

If the temperature rise is outside the rec-

ommended range, it may be adjusted on

direct drive equipped units by selecting

alternate circulation fan motor speeds. If

the temperature rise is too high, speed

the fan up. If the temperature rise is too

low, slow the fan down.

C) Keep in mind that the stack tem-

perature varies directly with the tempera-

ture rise. The higher the temperature

rise, the higher the stack temperature will

be, resulting in lower efficiency. The

lower the temperature rise, the lower the

stack temperature will be, which, in some

cases, may allow condensation to form

in the chimney and other vent parts.

D) Test the high limit control to ensure

that it is operating correctly. This may be

done by temporarily removing the circu-

lator fan heating wire or neutral wire.

Turn of electrical power to the furnace

before working with the motor wires. Be

sure to protect any removed wires from

shorting out on metal furnace parts. If the

high limit test is successful, shut off the

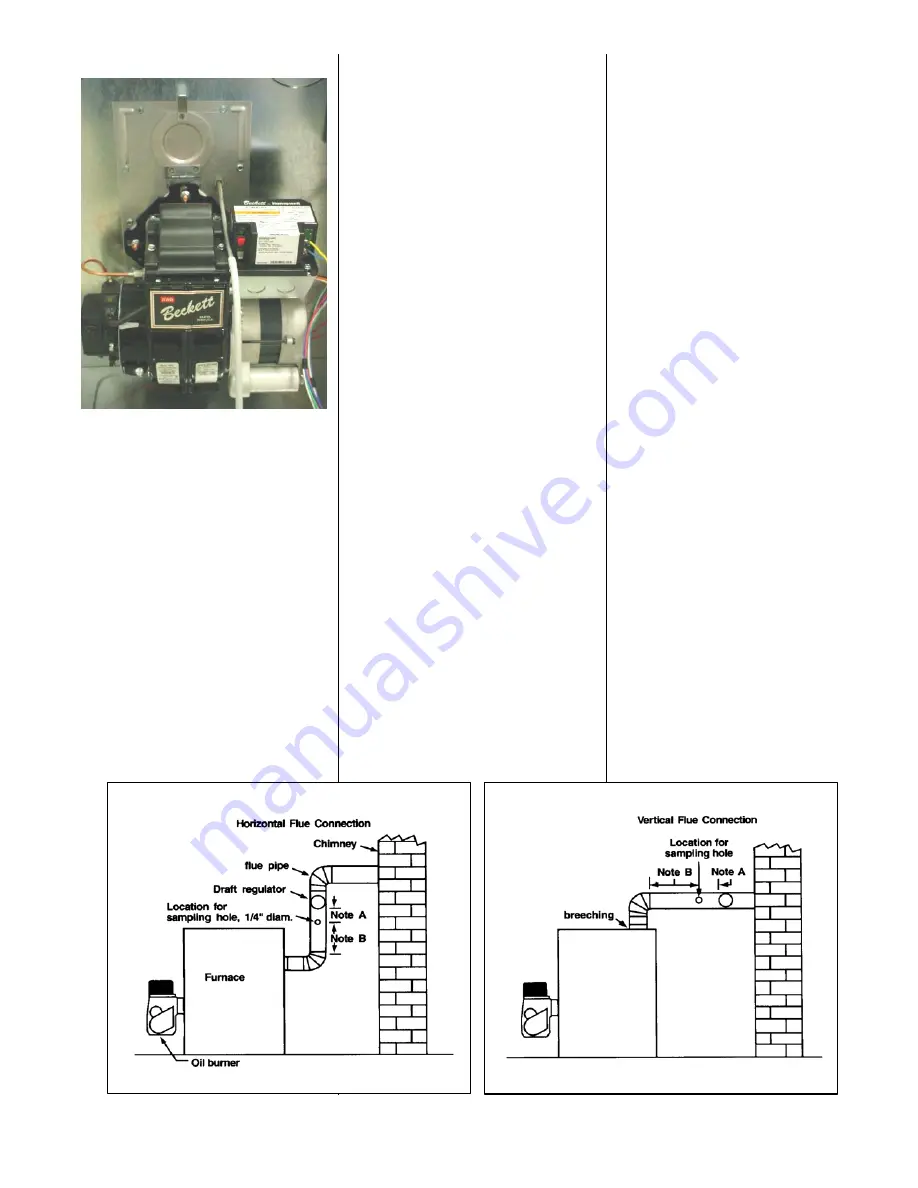

Fig.5 Vertical Smoke test Loca-

Fig.4 Horizontal Smoke test Loca-

Содержание P3HMX12F08001

Страница 16: ...16 APPENDIX A WIRING DIAGRAM ...