22

R7184 LED DIAGNOSTIC LIGHT

The LED diagnostic light has several

functions. It indicates the state or mode

in which the oil burner is operating. It will

also indicate fault conditions, and help

determine cad cell resistance while the

burner is operating.

NORMAL CONDITIONS

:

The LED diagnostic light will turn on

when the burner enters the carryover

state; the point at which ignition spark is

on, and will remain on through the run

state, where the ignition spark is termi-

nated but the burner continues to fire.

The LED diagnostic light will turn off at

the end of the burner cycle as the R7184

enters the idle state, and will remain off

until the next heating cycle.

FAULT CONDITIONS

:

If the LED diagnostic light is flashing

quickly; 1 Hz (½ second on / ½ second

off), the R7184 is in the lockout state or

in restricted mode. To exit the lockout

state, press the reset button.

If the LED diagnostic light is flashing

slowly; ¼ Hz (2 seconds on / 2 seconds

off), the R7184 is in the recycle state.

This indicates that flame sensing was

lost after the lockout timer expired during

the ignition carryover state. The R7184

will return to the idle state within 60 sec-

onds.

CAD CELL CONDITION

:

If the LED diagnostic light is off, the cad

cell is not sensing flame.

If the LED diagnostic light is on, the cad

cell is sensing flame, or viewing ambient

light.

The resistance of the cad cell may be

checked while the R7184 is in the run

state by pressing the reset button. The

LED diagnostic light will flash the follow-

ing code:

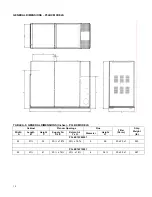

Flashes

Resistance in Ohms

1 Less

than

400

2

Between 400 - 800

3

Between 800 – 1600

4

Between 1600 - 5000

Table C-2: Cad Cell Resistance

Troubleshooting

IMPORTANT

:

Due to the potential hazard of line

voltage, only a trained, experienced

service technician should perform the

troubleshooting procedure.

PRELIMINARY STEPS

:

Check the diagnostic light for indications

of burner condition. Refer to R7184 LED

DIAGNOSTIC LIGHT

section for details.

When simulating a call for heat at the

R7184, disconnect at least one thermo-

stat lead wire from the T1 - T2 terminals

to prevent damage to the thermostat.

Neglecting this procedure may burn out

the heat anticipator of a standard 24

VAC

thermostat, or cause harm to compo-

nents within a micro-electronic thermo-

stat.

Before checking the oil primary control,

perform these preliminary checks, (repair

or replace controls as necessary):

•

Check the power supply, fuse box or

breaker, any service switches, all wir-

ing connections, and burner motor re-

set button (if equipped).

•

Check the limit switches to ensure that

the switch contacts are closed.

•

Check the electrode gap and position.

•

Check the contacts between the oil

primary control and the electrodes.

•

Check oil supply (tank gauge).

•

Check the oil nozzle, oil filter, and oil

valves.

•

Check the piping or tubing to the oil

tank.

•

Check the oil pump pressure.

CHECK OIL PRIMARY CONTROL AND

IGNITOR

If the trouble does not appear to be in

the burner or ignition hardware, check

the oil primary control and the ignitor by

using the following equipment:

Screwdriver.

Voltmeter (0 - 150

VAC

)

Insulated jumper wires with both ends

stripped.

ELECTRICAL SHOCK HAZARD

.

Troubleshooting is done with the system

powered. Be careful to observe all nec-

essary precautions to prevent electrical

shock or equipment damage.

PRELIMINARY CHECKS

:

Make sure that limit switches are closed

and that contacts are clean.

Check for line voltage power on the oil

primary control black and white lead

wires.

Refer to Table C-3 or C-4 for further

troubleshooting information.

Содержание P3HMX12F08001

Страница 16: ...16 APPENDIX A WIRING DIAGRAM ...