6

not interfere with the combustion air

supplied to the burner. The control

should be located a minimum of 3 flue

pipe diameters from the furnace breech-

ing and installed in accordance to the

instructions supplied with the regulator.

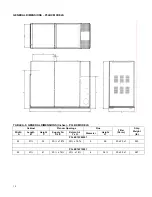

Table 3: Minimum Chimney Base

Temperatures (°F)

Chimney Height (ft.)

Nozzle

11 20 28 36

Chimney Thermal Resistance < R6

0.50 300

400

535

725

0.65 275

340

430

535

0.70 270

330

405

505

0.75 260

320

380

475

0.85 250

300

355

430

1.00 255

300

365

430

Chimney Height (ft.)

Nozzle

11 20 28 36

Chimney Thermal Resistance > R6

0.50 185

200

220

250

0.65 175

185

205

220

0.70 175

185

195

215

0.75 175

185

195

210

0.85 165

185

195

205

1.00 165

185

195

205

< -

Less than

, > -

greater than

OIL TANK

Oil storage tanks must be selected and

installed in compliance with applicable

codes; in the United States,

NFPA 31,

Standard for the Installation of Oil

Burning Equipment,

Chapter 2. and in

Canada,

CAN/CSA-B139, Installation

Code for Oil Burning Equipment

, Sec-

tion 6. Observe all local codes and by-

laws.

In general, the oil tank must be properly

supported and remain stable in both

empty and full condition. The oil tank

must be fitted with vent and supply pipes

to the outdoors. Refer to the above-

mentioned codes for sizing. The vent

pipe must be no less than 1¼ inches

I.P.S., and terminate with an appropriate

vent cap in a location where it will not be

blocked. The fill pipe must be no less

than 2 inches I.P.S., and terminate with

an appropriate cap in a location where

debris will not enter the fill pipe during oil

delivery.

If located indoors, the tank should nor-

mally be in the lowest level, (cellar,

basement, etc.). It must be equipped

with a shut-off valve at the tank outlet

used for the oil supply. The oil tank must

be located as to not block the furnace /

room exit pathway. Observe all clear-

ances specified in the above-mentioned

codes.

PIPING INSTALLATION

In the United States,

NFPA 31, Stan-

dard for the Installation of Oil Burning

Equipment, Chapter 2

.

In Canada, the entire fuel system should

be installed in accordance with the re-

quirements of

CAN/CSA B139

, and local

regulations. Use only approved fuel oil

tanks piping, fittings and oil filters.

Ensure that all fittings used in a copper

oil line system are high quality flare fit-

tings. Do not use compression fittings.

Do not use Teflon tape on any fittings.

Pressurized or gravity feed installations

must not exceed 3 PSIG. Pressures

greater than 10 PSIG may cause dam-

age to the shaft seal. If the height of the

oil stored in a tank above the oil burner

exceeds 11½ feet, it may be necessary

to use a pressure-regulating device ap-

proved for this purpose.

The furnace may be installed with a one-

pipe system with gravity feed or lift. The

maximum allowable lift on a single line

system is 8 feet. Lift should be measured

from the bottom (outlet) of the tank, to

the inlet of the burner. Sizing a single

line system is complex because of the

difficulty estimating the pressure drop

through each fitting, bend and compo-

nent in the line. In general, keep single

line systems short as possible. 2-stage

oil pumps are not available for either the

P3HMX or P3LBX

furnaces. The follow-

ing chart shows the allowable line

lengths (hori vertical) for single

and two-line oil piping systems. All dis-

tances are in feet.

In retrofit applications, where an existing

oil line system is in place, a vacuum

check will help determine the efficacy of

the existing oil line system The vacuum

in a system should not exceed 6” Hg. for

a single pipe system, nor 12” Hg. for a

two-pipe system.

NOTE

: The oil burner requires the use of

a bypass plug when converting from

single-pipe to two-pipe oil piping sys-

tems. See burner manufacturer’s instruc-

tions.

All fuel systems should include an oil

filter between the fuel oil storage tank

and the oil burner. For best results, in-

stall the oil filter as close to the burner as

possible. When using an indoor oil tank,

the oil filter may be installed at the tank

downstream from the shut-off valve. If

firing the furnace under the 0.65 gph

rate, a 7 to 10 micron line filter should be

installed as close to the oil burner as

possible.

Table 4: Oil Lines

Copper Tubing Oil Line Length (Feet)

Single-Pipe Two-Pipe

Lift

(Feet)

3/8”

OD

1/2”

OD

3/8”

OD

1/2”

OD

0 53 100 68 100

1 49 100 65 100

2 45 100 63 100

3 41 100 60 100

4 37 100 58 100

5 33 100 55 100

6 29 100 53 100

7 25 99 50 100

8 21 83 48 100

9 17 68 45 100

10 13 52 42 100

12

- - -

- - -

37

100

14

- - -

- - -

32

100

16

- - -

- - -

27

100

18

- - -

- - -

22

88

ELECTRICAL CONNECTIONS

The furnace is listed by the

Canadian

Standards Association (CSA)

. It is

factory wired and requires minimal field

wiring. In the United States, the wiring

must be in accordance with the

National

Fire Protection Association

NFPA-70

,

National Electrical Code

, and with local

codes and regulations. In Canada, all

field wiring should conform to

CAN/CSA

C22.1 Canadian Electrical Code, Part

1

, and by local codes, where they pre-

vail.

The furnace should be wired to a sepa-

rate and dedicated circuit in the main

electrical panel; however, accessory

equipment such as electronic air clean-

ers and humidifiers may be included on

the furnace circuit. Although a suitably

located circuit breaker can be used as a

service switch, a separate service switch

is advisable. The service switch is nec-

essary if reaching the circuit breaker

involves becoming close to the furnace,

or if the furnace is located between the

circuit breaker and the means of entry to

the furnace room. The furnace switch

(service switch) should be clearly

marked, installed in an easily accessible

area between the furnace and furnace

room entry, and be located in such a

manner to reduce the likelihood that it

would be mistaken as a light switch or

similar device.

Содержание P3HMX12F08001

Страница 16: ...16 APPENDIX A WIRING DIAGRAM ...