Maintenance and inspection

9

-

64

9.5

Axis motors

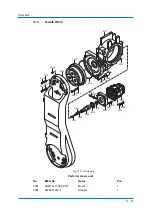

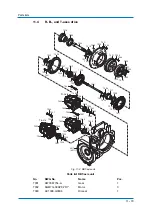

For the all axis motors, there are holes for grease-leakage detection. Remove the screws

from the holes to check for grease leaking from the motor. For these procedures of each

axis, refer to figure “Positions of grease-leakage detection hole".

When grease leakage is detected, contact YASKAWA representative.

For the “ * ”parts, the screw whose head faces to the ground must be removed to check the

hole.

Positions of grease-leakage detection hole

Grease-leakage detection hole

for L-axis (Hexagon socket

head plug PT1/8)

Grease-leakage detection hole

for S-axis (Hexagon socket

head plug PT1/8).

Grease-leakage detection hole

for R-axis

Grease-leakage detection hole

for B-axis

Grease-leakage detection hole

for T-axis

Grease leakage detection tube

for U-axis (Ø 6)

“ * ” part: Grease-leakage de-

tection hole for R-, B-, and T-

axes

1

2

3

4

5

6

7