36

VF2400

6. Adjustments

6.12.3 Pressure of elastic feed roller

Before adjusting, ALWAYS turn the motor switch OFF

and check that the motor has already stopped.

6.12.4 Maintenance of metering device

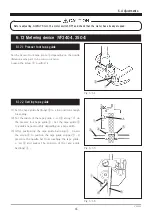

Fig. 6-39

Fig. 6-38

⑦

Fig. 6-37

①

②

③

①

④

⑤

⑥

⑥

To adjust the pressure of an elastic tape with tension

roller(small) ① , loosen the lock nut ② and turn the ad

-

justing screw ③ .

● To increase the pressure, turn the adjusting screw ③

clockwise.

● To decrease the pressure, turn the adjusting screw ③

counterclockwise.

Keep the pressure as low as possible.

Too tight or loose pressure can cause uneven feeding of a

tape.

Too much change in tension of a tape from the bobbin

may occur uneven sewing finish size even if the tension

roller(large) feeds an elastic tape correctly.

An automatic elastic feeder “AEF-31”can feed an elas-

tic tape smoothly and constant sewing finish can be ob-

tained.

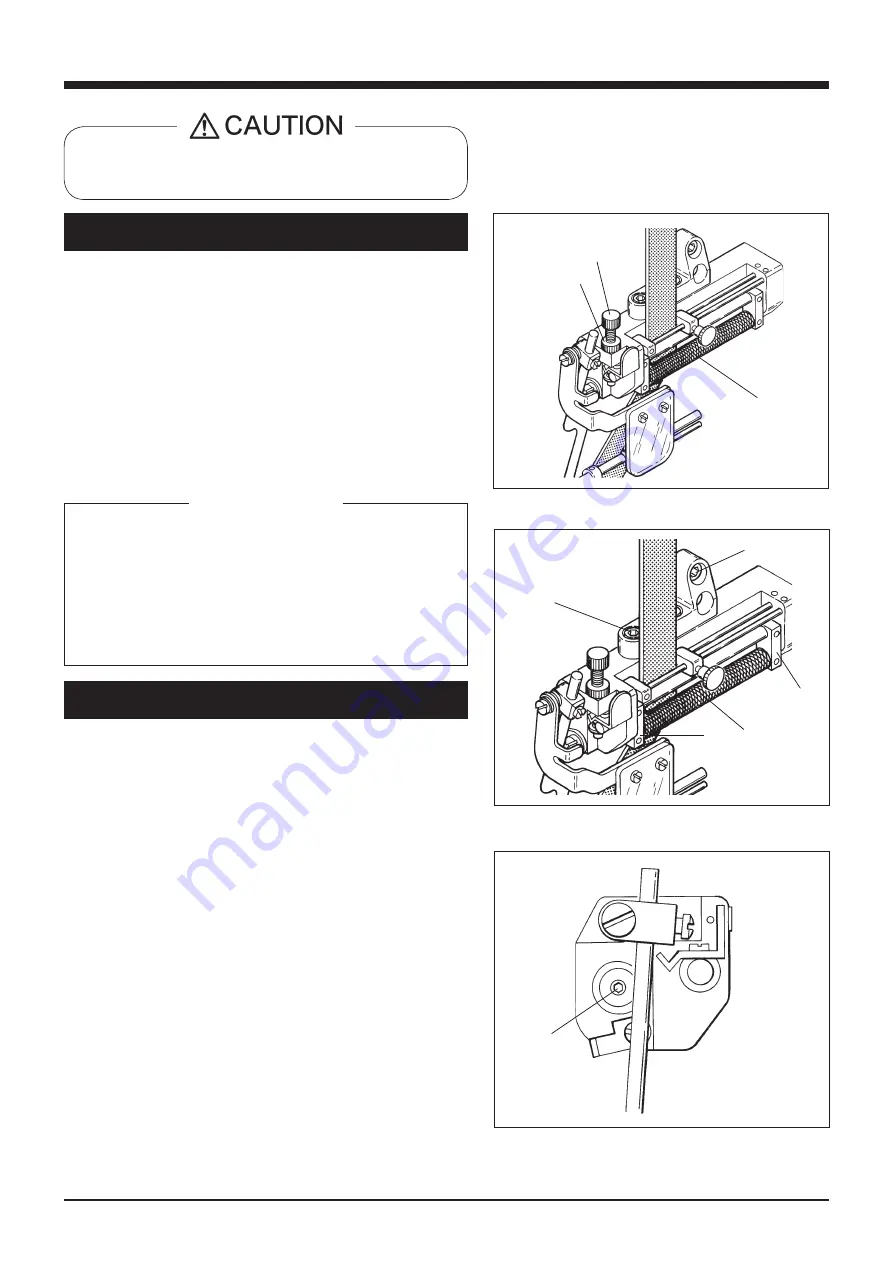

REFERENCE

Replacement and repair:

Improper installation of the metering device can cause im-

proper feeding of an elastic tape, skip stitch, needle break-

age, bad sewing performance and others.

Carefully install the device as following points:

Lubrication:

Remove the screws ⑦ on the roller shaft to supply grease

on each part several times a year.

(1) Check that the roller shaft turns smoothly after set-

ting it. Loosen the screws ④ and ⑤ and make inter

-

lining to adjust it.

(2) Set the tension roller(small) ① to turn smoothly like

a top. Improper turning of it can cause irregular

feeding of a tape.

(3) Set the tension link ⑥ and its shaft to turn smoothly.

(4) Set the tension spring pressure of the tension

roller(small) ① as low as possible so that it can fol

-

low the rotation.