41

Maintenance

For maintenance

For maintenance, turn the breaker and power supply off for safety. If the chamber is hot, wait for

it to cool. Wipe off any dirt on the exterior with a damp cloth. Do not use benzene, thinner or

cleanser to wipe, nor scrub with a brush.

Daily Maintenance

Cleaning after liquid loads

Biological media tends to boil at a higher rate compared to other liquids. This can cause media

to be splattered inside the chamber. Therefore, the chamber must be cleaned daily with a damp

cloth after temperature has cooled.

Weekly Maintenance

Cleaning the inside of the chamber

Clean the inside of the chamber with a clean damp cloth. Do not pull the filter out, located in the

bottom center when cleaning the inside of the chamber. If cleaned without the filter inside, the

pipe can get clogged with debris.

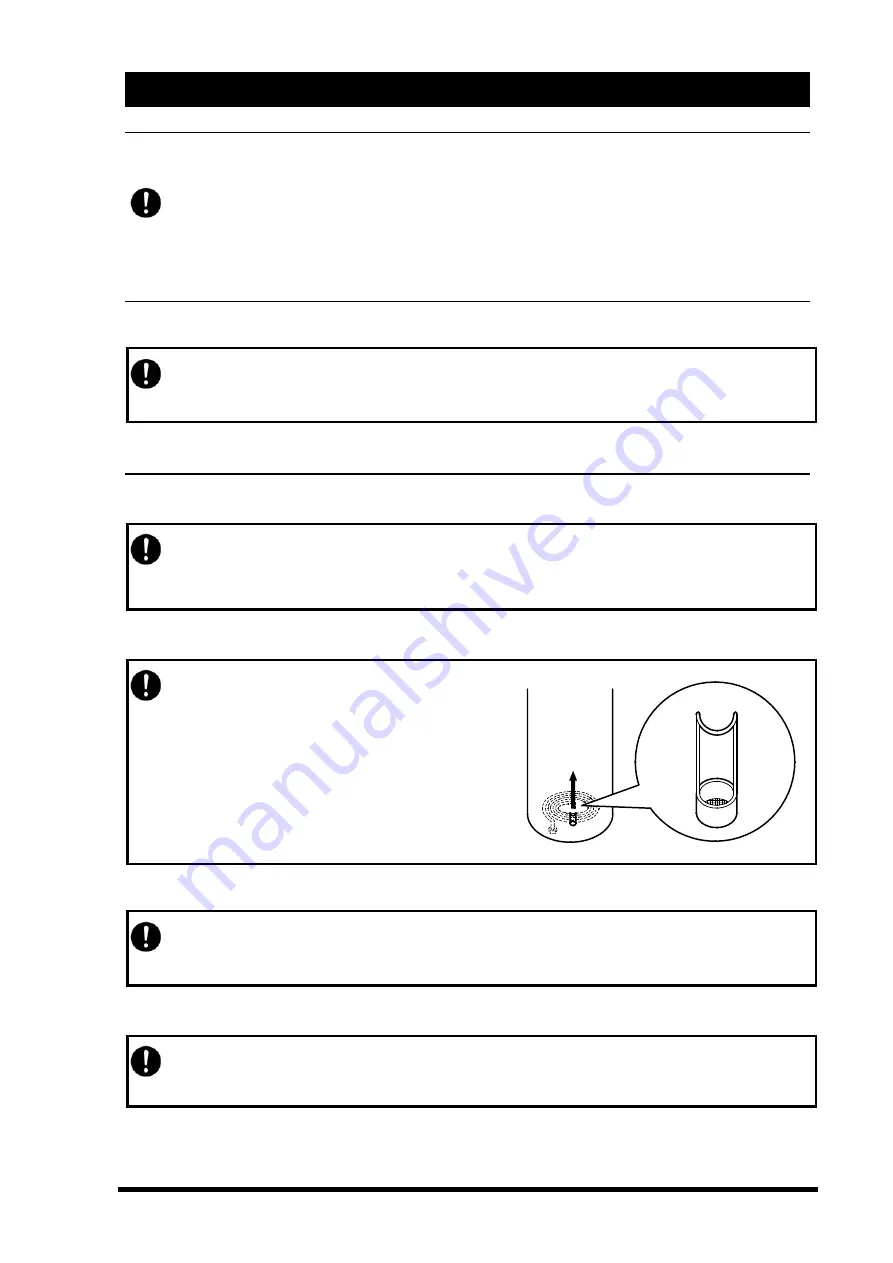

Filter cleaning

If the filter in the bottom center of the chamber is

clogged, drainage is prevented. Clean the filter in

appropriate intervals, according to frequency of

use.

Pull the filter out, from the bottom drain port. The

filter may be cleaned under the water faucet.

Cleaning the Door Gasket

The door gasket, located under the lid of the sterilizer can be wiped clean with a clean damp

cloth. The gasket should be examined for cracks or damage that can result in a poor pressure

seal. If replacement is needed, contact Yamato Scientific.

Cleaning the Pipe Heater

The pipe heater should be cleaned twice a month.

Accumulation of scale build up results in poor heat transfer and high sheath temperatures.

Содержание SM200

Страница 26: ...24 Program MODE Flowchart ...

Страница 40: ...38 Wiring Diagram SM200 X SM300 Inside of dashed line is option ...