14

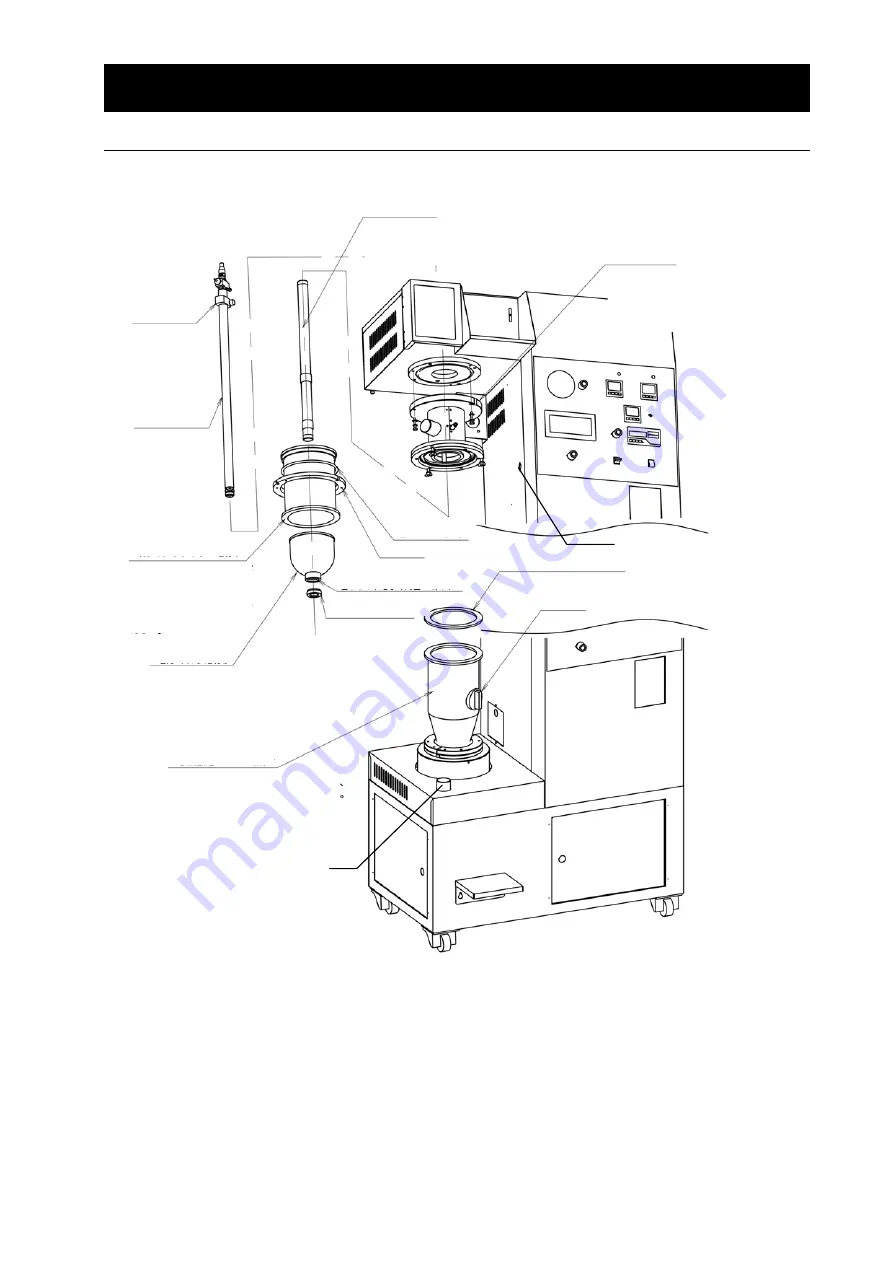

4. Operating procedures

Preparations

(

3

)

Install parts following the procedures in the order of their numbers.

(

4

)

Turn the POWER switch ON and raise the stage with UP of the lift switch. Stop moving the stage

once when the upper part of the flow layer chamber is close to the flange of the filter chamber,

and then turn the UP switch ON intermittently until the top flange of the flow layer chamber is

aligned with the packing and the flange of the filter chamber and the stage is stopped.

(

5

)

Install the temperature sensor to the pipe of the interim pipe and insert the plug into the socket

on the side of the main body.

(

6

)

Install the suction hose to the pipe of the interim pipe and the pipe at the left front of the stage

and fix them with hose clips.

温度センサ取付用ソケット

吸気ホース接続口

2. Installing the pipe

Fix this to an appropriate

position with a knurled

screw.

Nozzle fixing clamp

Install the interim pipe at three positions with M6 x

30 hex bolts (with flat washers and spring washer).

Top surface of interim pipe: with O ring P16

Groove on bottom surface of interim pipe: with O

ring P135

Upper inside of interim pipe: with O ring P30

1. Installing the interim pipe

3. Inserting the nozzle

2. Installing the pipe

Insert the pipe into the interim pipe and twist it

to the internal thread until it completely stops.

Take care for top and bottom directions.

4. Installing the filter chamber

Insert the nozzle from

the insert hole at the top

of the body.

Put the filter from under the filter

chamber through the pipe and push it

against the bottom surface of the interim

pipe. Screw it into the bottom end of the

filter retainer nut pipe, and push it up so

that the filter contacts with the interim

pipe without any gaps.

Hold the chamber with its stepped

flange up, install an O ring to the

stepped part, hook the butterfly nut on

the interim pipe to the groove on the

flange to fix.

5. Installing the filter

6. Installing the flow layer chamber

Make sure that on O ring is set in the stage, and

set the chamber so that two pins are aligned with

the grooves correctly. The cap will be the near

side.

O ring P145

Flange

O ring P30 (installed inside)

Filter retainer nut

Silicon packing (t5mm)

Cap

Temperature sensor socket

Suction hose connection port

Содержание PULVIS MINI BED GB210B

Страница 39: ...37 8 When a trouble occurs Confirmation of GB210A manual and language selection display ...

Страница 40: ...38 8 When a trouble occurs Confirmation of GB210A manual and language selection display ...

Страница 41: ...39 8 When a trouble occurs Confirmation of GB210B manual and language selection display ...

Страница 42: ...40 8 When a trouble occurs Confirmation of GB210B manual and language selection display ...