3

Pressure measuring method

Pressure receiving element

Gas to be measured

Pressure setting method

Standard installation position

Medium and ambient

temperature

Ambient humidity

Withstanding pressure

of instrument body

Withstanding pressure

of receiving element

Withstanding vibration

Withstanding impact

Insulation resistance

Withstand voltage

Material of the outer case

Applicable piping

Piping connector polarity

Cable connection

terminal screws

Mass

Accessory

Conformed standards

Caution

Measuring differential pressure

Diaphragm

(for material information, refer to “Pressure ranges and characteristics” )

Air, non-corrosive and non-combustible gases (not liquid)

Dial with scale

Installation position from upward horizontal to vertical is available (refer to p.6)

- 10 to + 50 ℃ (no freezing)

90 % RH or less (no dewing)

200 kPa

40 kPa

5 to 10 Hz Amplitude : 10 ㎜ ,

10 to 50 Hz Acceleration : 39 m/s

2

(each two hours on triaxial directions)

100 m/s

2

(each six times on triaxial direction)

Between each terminal and case 20 MΩ or more (500 V DC megger)

Between each terminal and case 1500 V AC 50 / 60 Hz, for one minute

Phenol resin and aluminum die cast

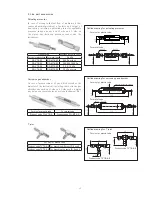

1. Vinyl, plastic or rubber tube (I.D. 6)

・・・ Piping applicable model attached with connector for vinyl or plastic tube

2. Metal tube (O.D. 6 ± 0.1)

・・・ Piping applicable model attached with connector for metal tube

3. Hard plastic tube (O.D. 6 × I.D. 4)

・・・ Inner sleeve set (XIN 6 × 4) is needed separately for type attached with piping

connector for metal tube.

The part of connector piping is marking “H” on high pressure side and “L” on low

pressure side.

M4 screws (three points)

MS65

Approximately 380 g

MS65F

Approximately 550 g

Nil

RoHS Directive (2002/95/EC)

(Products in compliance with the RoHS carry

G

or [[

G

]] mark on the label of

product itself and on each package.)

In case of measuring combustible gas and using in combustible gas area, use with

intrinsically safe apparatus construction.

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

: