5-23

VALVES AND VALVE SPRINGS

3. Eliminate:

• Carbon deposits

(from the valve face and valve seat)

4. Check:

• Valve face

Pitting/wear •Grind the valve face.

• Valve stem end

Mushroom shape or diameter larger than

the body of the valve stem

→

Replace the

valve.

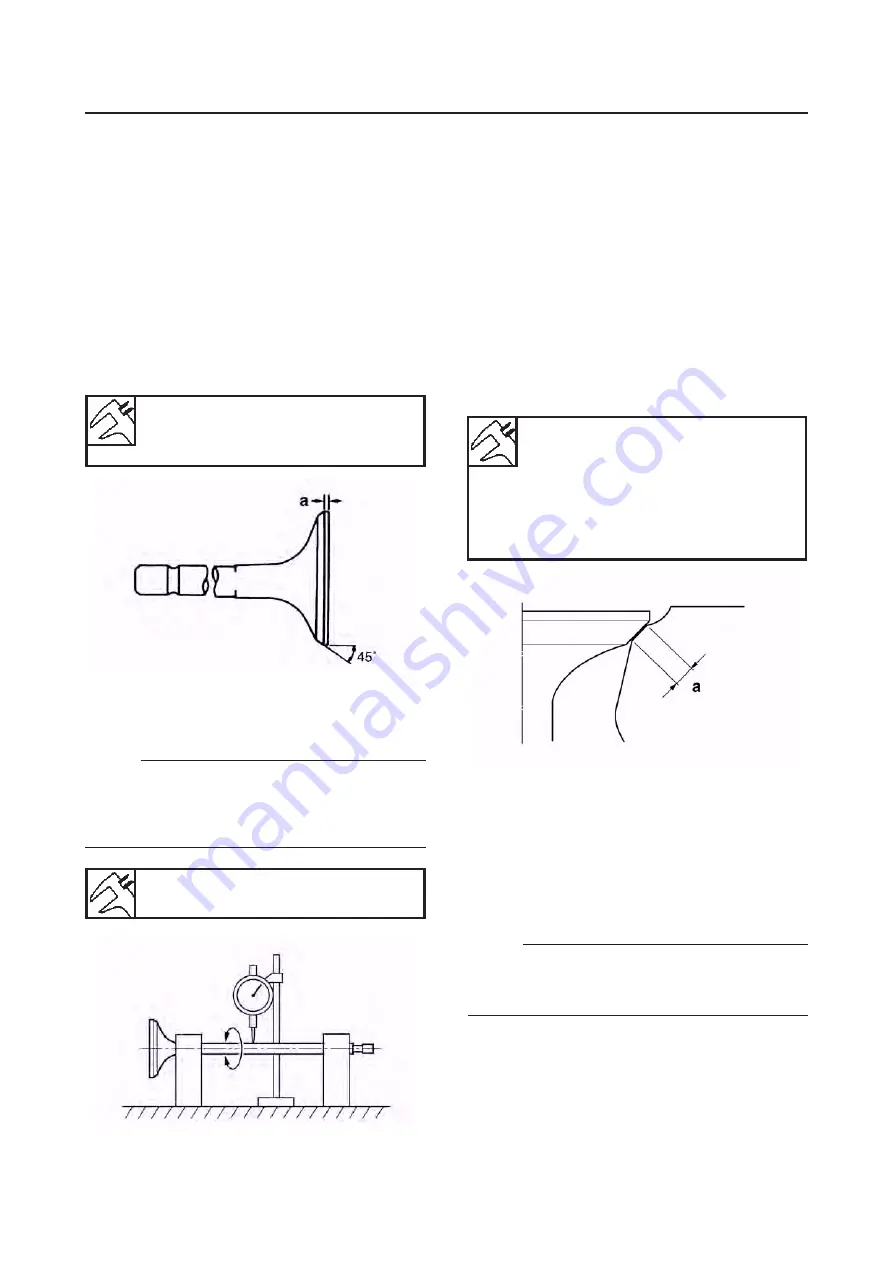

5. Measure:

• Valve margin thickness “a”

Out of specification

→

Replace the valve.

Valve margin thickness

0.80-1.20 mm

(0.0315-0.0472 in)

6. Measure:

• Valve stem runout

Out of specification

→

Replace the valve.

NOTE:

• When installing a new valve, always replace

the valve guide.

• If the valve is removed or replaced, always re-

place the valve stem seal.

Valve stem runout

0.010 mm (0.0004 in)

EAS00240

CHECKING THE VALVE SEATS

The following procedure applies to all of the

valves and valve seats.

1. Eliminate:

• Carbon deposits

(from the valve face and valve seat)

2. Check:

• Valve seat

Pitting/wear

→

Replace the cylinder head.

3. Measure:

• Valve seat width “a”

Out of specification

→

Replace the cylinder

head.

Valve seat width

Intake

1.00-1.20 mm

(0.0394-0.0472 in)

Exhaust

1.00-1.20 mm

(0.0394-0.0472 in)

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Apply Mechanic’s blueing dye (Dykem) onto

the valve face.

b. Install the valve into the cylinder head.

c. Press the valve through the valve guide and

onto the valve seat to make a clear impres-

sion.

d. Measure the valve seat width.

NOTE:

Where the valve seat and valve face contacted

one another, the blueing will have been re-

moved.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Содержание MT-03

Страница 7: ......

Страница 9: ......

Страница 25: ......

Страница 51: ...2 26 COOLING SYSTEM DIAGRAMS EAS00033 COOLING SYSTEM DIAGRAMS 5VK 5VK00 A 4 A B 4 3 2 1 2 3 1 A A A ...

Страница 53: ...2 28 COOLING SYSTEM DIAGRAMS 1 2 3 4 5 6 7 8 9 5 10 11 A B C ...

Страница 56: ...2 31 LUBRICATION CHART Pressure feed Splashed scavenge ...

Страница 57: ...2 32 LUBRICATION DIAGRAMS LUBRICATION DIAGRAMS A A 1 3 2 2 4 A A A A ...

Страница 58: ...2 33 LUBRICATION DIAGRAMS 1 Oil delivery hose 2 2 Oil strainer 3 Oil delivery hose 1 4 Oil tank ...

Страница 59: ...2 34 LUBRICATION DIAGRAMS A A A A 3 1 2 3 4 ...

Страница 60: ...2 35 LUBRICATION DIAGRAMS 1 Oil delivery pipe 2 2 Oil delivery pipe 1 3 Oil filter 4 Oil pump ...

Страница 61: ...2 36 LUBRICATION DIAGRAMS 1 7 2 3 4 5 6 A ...

Страница 63: ...2 38 LUBRICATION DIAGRAMS 1 6 5 4 3 2 ...

Страница 64: ...2 39 LUBRICATION DIAGRAMS 1 Camshaft 2 Oil delivery pipe 1 3 Oil filter 4 Main axle 5 Drive axle 6 Crankshaft ...

Страница 65: ...2 40 CABLE ROUTING CABLE ROUTING ...

Страница 67: ...2 42 CABLE ROUTING ...

Страница 69: ...2 44 CABLE ROUTING ...

Страница 71: ...2 46 CABLE ROUTING ...

Страница 73: ...2 48 CABLE ROUTING ...

Страница 75: ...2 50 CABLE ROUTING ...

Страница 77: ...2 52 CABLE ROUTING ...

Страница 79: ...2 54 CABLE ROUTING ...

Страница 81: ...2 56 CABLE ROUTING ...

Страница 83: ...2 58 CABLE ROUTING ...

Страница 85: ...2 60 CABLE ROUTING ...

Страница 87: ......

Страница 121: ......

Страница 177: ...4 54 FRONT FORK WARNING Make sure the brake hoses are routed prop erly ...

Страница 271: ......

Страница 273: ......

Страница 287: ......

Страница 325: ......

Страница 339: ...8 12 CHARGING SYSTEM 2 A C magneto 5 Rectifier regulator 7 Battery 8 Main fuse ...

Страница 341: ...8 14 CHARGING SYSTEM ...

Страница 355: ...8 28 COOLING SYSTEM ...

Страница 365: ...8 38 IMMOBILIZER SYSTEM ...

Страница 366: ...8 39 ELECTRICAL COMPONENTS EAS27970 ELECTRICAL COMPONENTS ...

Страница 368: ...8 41 ELECTRICAL COMPONENTS ...

Страница 370: ...8 43 ELECTRICAL COMPONENTS EAS27980 CHECKING THE SWITCHES ...

Страница 389: ......

Страница 391: ......

Страница 397: ...COLOR CODE ...

Страница 398: ......

Страница 399: ...YAMAHA MOTOR ITALIA S P A ...

Страница 400: ...MT 03 2006 WIRING DIAGRAM ...