Electric Chain Hoist CPE/F

8

7. OPERATION

Installation, service, operation

Operators delegated to install, service or independently operate the

hoist must have had suitable training and be competent. Operators are

to be specifi cally nominated by the company and must be familiar with

all relevant safety regulations of the country of use.

5. FUNCTIONAL CHECK AFTER ASSEMBLY

Prior to operating the hoist, grease the trolley pinions (manual geared

and electric trolleys) and lubricate the load chain when it is not under

load (see page 9).

Before the hoist is put into regular service, following additional inspec-

tions must be made:

• Are all screwed connections on hoist and trolley tight and are all locking

devices in place and secure?

• Are the end stops on the trolley runway in place and secure?

• Is the chain drive correctly reeved?

• Is the chain end stop correctly fitted to the loose end of the load chain?

• All units equipped with two or more chain strands should be inspected

before initial operation for twisted or kinked chains. The chains of

2-strand hoists may be twisted if the bottom block is rolled over.

• Perform an operation cycle without load. The chain should move in a

steady, smooth way. Check the function of the overload device by raising

the bottom block against the hoist body (max. 5 sec.).

• Check the brake function when lifting and lowering. The braking

distance must not be more than 50 mm.

• Traverse the trolley (if available) the complete length of the trolley runway

ensuring that the 2 - 4 mm lateral clearance between the trolley wheel

flange and the beam outer edge is maintained at all times. Check that

beam end stops are positioned correctly and secure.

6. COMMISSIONING

Inspection before initial operation

Each hoist/trolley must be inspected prior to initial operation by a com-

petent person and any failures be removed. The inspection is visual and

functional. These inspections have to assure that the hoist is safe and

has not been damaged by incorrect transport or storage. Inspections

should be made by a representative of the manufacturer or the supplier

although the company can assign its own suitably trained personnel.

Inspections are instigated by the user.

Inspection by a crane expert

If the hoist is used as a crane, it has to be inspected and approved by a

crane expert before initial operation. This inspection has to be registered

in the crane inspection book. The inspection by the crane expert has to

be instigated by the operating company.

Inspection before starting work

Before starting work inspect the hoist/trolley, chains and all load bearing

components every time for visual defects. Furthermore test the brake

and make sure that the load and hoist/trolley are correctly attached by

carrying out a short work cycle of lifting and lowering resp. travelling in

both directions. Selection and calculation of the proper suspension point

and beam construction are the responsibility of the operating company.

Inspection of load chain

Inspect the chain for suffi cient lubrication and visually check for external

defects, deformations, superfi cial cracks, wear or signs of corrosion.

Inspection of chain end stop

The chain end stop must be connected to the free (idle) chain strand

(see Fig. 1 - chain end stop).

Inspection of chain reeving

All units with two or more chain strands should be inspected prior to initial

operation for twisted or kinked chains. The chains of 2-strand hoists may

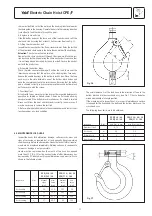

be twisted if the bottom block was rolled over (Fig. 13).

The load chain has to be installed according to illustration (Fig. 9). Hereby

the welds on the standing links must face away from the load sheave.

Inspecting the hooks

Check the load hook and the suspension hook for deformations, cracks,

damages, abrasion and signs of corrosion.

Attaching the load

The load must always be seated in the saddle of the hook. Never attach

the load to the tip of the load hook (Fig. 14). This also applies to the

suspension hook.

Inspect the traverse (for trolleys)

Inspect the traverse for correct assembly and visually check for external

defects, deformations, superfi cial cracks, wear or signs of corrosion.

Especially make sure that the roll pins are properly fi tted to the centre

traverse (Fig. 10).

Check adjustment of trolley width

On chain hoists with trolley (CPV/F-VTP/G(E) check that the clearance

between the trolley wheel fl ange and the beam outer edge is equal on

both sides and within the tolerances given (see page 5, Fig. 10).

Enlarging the clearances, e. g. to enable the trolley to negotiate tighter

curves, is forbidden.

Traversing the hoist

Plain trolley:

Push the hoist or attached load.

Attention:

Never pull on the pendant control cable. Suspended loads

may only be pushed.

Geared trolley:

By operating the trolley hand chain.

Fig. 13

Fig. 14

Содержание CPEF

Страница 15: ...Electric Chain Hoist CPE F 15...

Страница 16: ...Electric Chain Hoist CPE F 16...

Страница 17: ...Electric Chain Hoist CPE F 17...