4

Installation

18

07.2020

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

4

Installation

WARNING

Improper assembly can cause material damage or severe injuries.

➢

Ensure that the supporting structure is designed for the maximum hoist load.

➢

Ensure that a competent person carries out the assembly.

➢

Adhere to the national and local safety and accident prevention regulations, the

occupational safety acts and environmental provisions.

➢

Work that cannot be carried out from floor level must always be carried out from lifting

platforms.

➢

Use a safety harness when performing any work outside of lifting platforms.

➢

Wear the prescribed personal protective equipment.

➢

Secure the danger zone.

➢

Maintain a sufficient safety distance from the product.

➢

Use only original mounting accessories from the manufacturer.

➢

Tighten the bolted connections to the specified tightening torques.

➢

Secure the trolleys during assembly, e.g. with straps, so that they cannot fall.

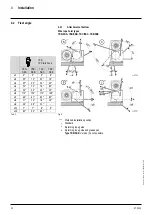

4.1

Stationary hoist

Fig. 6

Type

M

T

(rope drum torque)

[lb

f

in]

YKA/SKA

M

T

= 0.5 × F × 5 in

YKB/SKB

M

T

= 0.5 × F × 6.6 in

YKC/SKC

M

T

= 0.5 × F × 8.6 in

YKE/SKE

M

T

= 0.5 × F × 14 in

Possible mounting positions and fleet angles

Feet “at bottom” and “at top” are possible for designs with bottom hook block (rope lead

-

off vertically downwards).

The YK/SK wire rope hoist with 1PS and 1PS twin hook rope lead-off can be installed in

various positions (fleet angles see section

4.2 Fleet angle

)

1.

If possible, install the hoist in the

preferred installation position

***

(see section

4.2.1 Attachment at bottom

)

2.

Use the fixing elements specified, see the following figures and tables.

3.

Take care that no distortion arises from unevenness (see figure item

A = max. 0.5°

,

item

B = max. 0.079 in

).

4.

The customer's substructure must take up the torque M

T

from the rope drum. It must

therefore be torsion resistant.

5.

If the rope lead-off is not vertical, the shearing forces arising must be taken up by a

shear bar.

6.

For tightening torques see chapter

Tightening torques.

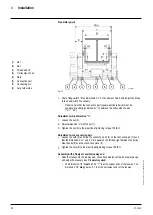

Standard reevings

1PS

2PS

4PS

1PD

2PD

4PD

Fig. 7