4

Installation

07.2020

25

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

4.2.5

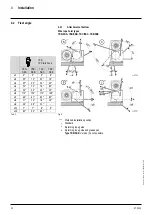

Angle of installation

WARNING

Rope damage hazard.

The wire rope must not touch the rope guide or structural

elements.

➢

Always install the hoist horizontal.

Fig. 11

1.

Install hoists with rope drives with bottom hook blocks always horizontal to their

longitudinal axis.

2.

Do not exceed the fleet angle to the direction of the rope drum groove and the rope

sheave of

4°/3°

for non-rotation-resistant wire ropes,

2°/1°

for rotation-resistant wire

ropes. However even at these angles a reduction in service life is to be expected.

Equip rope sheaves with a suitable guard to prevent the rope jumping out of the

groove, max. clearance of the guard

<0.5

×

rope diameter

. The rope must not slip

off the sheave axle if the sheave breaks. The rope suspension must be designed to

prevent kinking and other additional stresses. The rope suspension for non-rotation-

resistant wire ropes must be designed so that it cannot rotate around its longitudinal

axis. The rope spread angle of

45°

in top hook position must not be exceeded.

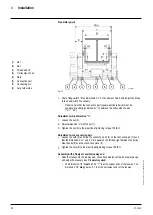

4.3

Monorail trolleys

The trolleys are constructed according to the state of the art and supplied with mounted

buffers.

NOTICE

Danger of material damage.

When using the optional hook operated hoist limit switch, this must be mounted in the

operating position before assembling the trolley, see the

Hook operated operational

hoist limit switch

(option) section.

4.3.1

Underslung trolley KE-S33

–

76

WARNING

If the setting is established with the incorrect nuts (marked in the figure

on the threaded rod end with an X), there is a risk of the load toppling.

➢

Only

perform setting work with the nuts (1) and (2).

Preparatory work

NOTICE

Danger of material damage

Modification of the flange width (on-site) can result in a change to the counterweight

being necessary, in order to avoid the trolley tipping.

➢

Have this checked by the manufacturer.