4

Installation

07.2020

31

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

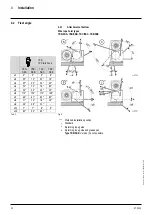

Assembly with an inaccessible runway end

Loosen the nuts (2) on the threaded bolts (3) and unscrew by dimension “x”.

Slide the trolley side cheeks (4) apart parallel, to the unscrewed nuts (2) until the

dimension “B” + “y” is reached.

Mount the trolley on the axle holder side (8) in the bottom flange of the runway beam

and secure against slipping down.

Slide the trolley side cheeks (4) back against the nuts (1).

–

When doing so, thread in the drive-through mechanism (see section 7.5).

Tighten the nuts (3) to the prescribed tightening torque 159 lb

f

ft.

Check the track clearance “f/2” with a feeler gauge and adjust if necessary (see

“Preparatory work”

).

–

The dimension “f/2”

must

be 0.02

+0.04

in at the widest point of the runway. The

dimension “f/2”

may

be max. 0.1 in at the narrowest point of the runway.

Type

Ø D

Trolley

B

c

x

y

z

max

[in]

[in]

YKE/SKE

7.9

UE-S776

7.3…19.7

B+3.6

*1

3.7

7.4

1.8

Tab. 9

*

1

with I (INP/IPN) EN 10024 beam: -0.08 in

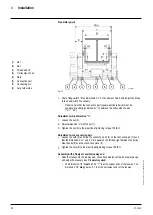

4.3.4

Articulated trolley (DKE-S4 / DKE-S6)

Fig. 17

WARNING

If the setting is established with the incorrect nuts (marked in the figure

on the threaded rod end with an X), there is a risk of the load toppling.

➢

Only

perform setting work with the nuts (1) and (2).