Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.mcdonnellmiller

.com

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

MAINTENANCE

SCHEDULE:

• Blow down weekly (at least once) when the

boiler is in operation.

• Disassemble and inspect annually. Replace

the low water cut-off if it is worn, corroded,

or if components no longer operate properly.

• Inspect the float chamber and equalizing

piping annually. Remove all sediment

and debris.

• Replace every 10 years.

More frequent replace-

ment may be required when severe conditions

exist such as rapid switch cycling, surging water

levels, and use of water treatment chemicals.

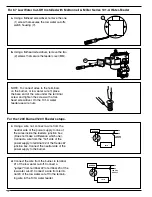

PROCEDURE:

1. Blow down the low water cut-off when the

water level is at its normal level and the

burner is on. Fully open the blow down

valve and observe the water level fall in the

gauge glass. Close the valve after verifying

that the feeder contacts have closed and

the burner shuts off. If this does not happen,

immediately shut off the boiler and correct

the problem.

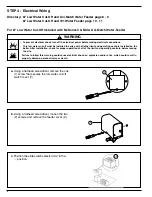

To prevent serious personal injury from steam and hot

water, make sure there is a discharge line from the

blow down valve to a proper place of disposal.

Failure to follow this caution could cause

personal injury.

!

CAUTION

INSTALLATION COMPLETE

For All Installations

BOTTOM

TOP

LEFT

RIGHT

The BX outlet (GG) on the control is movable

into any of the four positions by simply

removing the two black-headed screws and

rotating the housing.

© 2014 Xylem Inc. MM-201H March 2014 Part No. 246752

Содержание McDonnell & Miller 67 Series

Страница 1: ...INSTRUCTION MANUAL MM 201H Series 67 and 767 Low Water Cut Offs For Steam Boilers...

Страница 9: ......