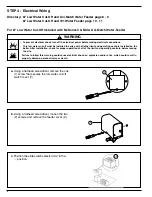

For the 24V Burner/24V Feeder setups.

BURNER

101A-24

120 VAC

SUPPLY

24V TRANSFORMER

(101-24V-48)

1

2

3

4

N

H

24V

69

c.

Connect the "hot" wire from the boiler trans-

former to terminal #2 of the low water cut-off.

Connect the "hot" side of the water feeder

transformer to terminal #3 of the low water

cut-off. Connect the neutral side of the boiler

transformer to the burner. Using a wire nut,

connect the neutral side of the water feeder

transformer to the water feeder.

BURNER

101A-24

120 VAC

SUPPLY

24V TRANSFORMER

(101-24V-48)

1

2

3

4

N

H

24V

d.

Connect the wire from the burner to terminal

#1 of the low water cut-off. Connect a wire

from terminal #4 of the low water cut-off to the

remaining wire in the water feeder. Wire nut

together.

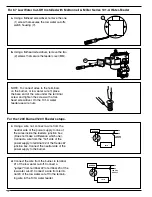

BURNER

101A

120 VAC

SUPPLY

N

H

24V

1

2

3

4

69

Wiring Alternative

For the 120V Burner/24V Feeder setups.

For the 24V Burner/120V Feeder setups.

BURNER

101A-24

120 VAC

SUPPLY

24V TRANSFORMER

(101-24V-48)

TO AVOID DAMAGE TO 101A

SOLENOID COIL, TRANSFORMER

101-24V-48 MUST BE USED.

N

H

1

2

3

4

69

11

IMPORTANT:

It is very important that you use the transformer supplied with the 101-A-24. The boiler

transformer in most cases is not big enough to handle the current draw of the 101-A-24.

Use the supplied transformer (101-24-48). In most cases it will handle both the boiler

and feeder.

Do not try to use two transformers in the same circuit.

Содержание McDonnell & Miller 67 Series

Страница 1: ...INSTRUCTION MANUAL MM 201H Series 67 and 767 Low Water Cut Offs For Steam Boilers...

Страница 9: ......