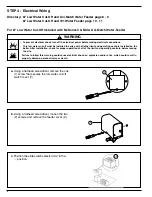

NOTE: To connect wires to the terminals

on the burner, or low water cut-off, place

the bare end of the wire under the terminal

screw and tighten the screw with a flat-

head screwdriver. On the 101-A water

feeder use wire nuts.

Y

a.

Using a flathead screwdriver, remove the one

(1) screw that secures the low water cut-offs

switch housing (Y).

BB

b.

Using a flathead screwdriver, remove the two

(2) screws that secure the feeder cover (BB).

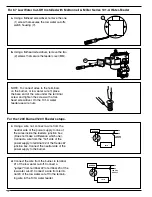

For 67 Low Water Cut-Off Installed with McDonnell & Miller Series 101-A Water-Feeder

For the 120V Burner/120V Feeder setups.

BURNER

120 VAC

SUPPLY

1

2

3

4

N

H

101A

69

c.

Using a wire nut, connect a wire from the

neutral side of the power supply to one of

the wires inside the feeders junction box.

(Does not make a difference which one).

Connect a wire from the "hot" side of the

power supply to terminal #2 of the Series 67

junction box. Connect the neutral side of the

power supply to the burner.

BURNER

120 VAC

SUPPLY

1

2

3

4

N

H

101A

d.

Connect the wire from the burner to terminal

#1 of the low water cut-off. Connect a

"jumper" from terminal #2 to terminal #3 of the

low water cut-off. Connect a wire from termi-

nal #4 of the low water cut-off to the remain-

ing wire in the 101A water feeder.

10

Содержание McDonnell & Miller 67 Series

Страница 1: ...INSTRUCTION MANUAL MM 201H Series 67 and 767 Low Water Cut Offs For Steam Boilers...

Страница 9: ......