Make sure the shaft extends into the hubs at least 0.8 times the diameter of the shaft.

6. Lightly fasten the hubs to the shafts in order to prevent them from moving during

alignment.

7. Align the hubs to the values shown in Maximum allowable misalignment for couplings.

You can perform alignment with lasers, dial indicators, or with a straight edge and

calipers.

4.2.2 Align the pump using a straight edge and calipers

For standard sleeve type coupler with black rubber insert

Before aligning the coupler, make sure there is at least 1/8” end clearance between the

sleeve and the two coupler halves.

1. Check the angular misalignment:

Tool

Procedure

Calipers

1. Measure the outside of one flange to the outside of the opposite flange at four points 90°

apart. Do not rotate coupler. Misalignment of up to 1/64 per inch of coupler radius is

permissible.

Feeler

gauges

1. Insert feeler gauges between the coupling faces at various points around the circumference.

Do not rotate the shafts.

2. Reposition the equipment until the difference between the minimum and maximum

distance values is within the permissible range.

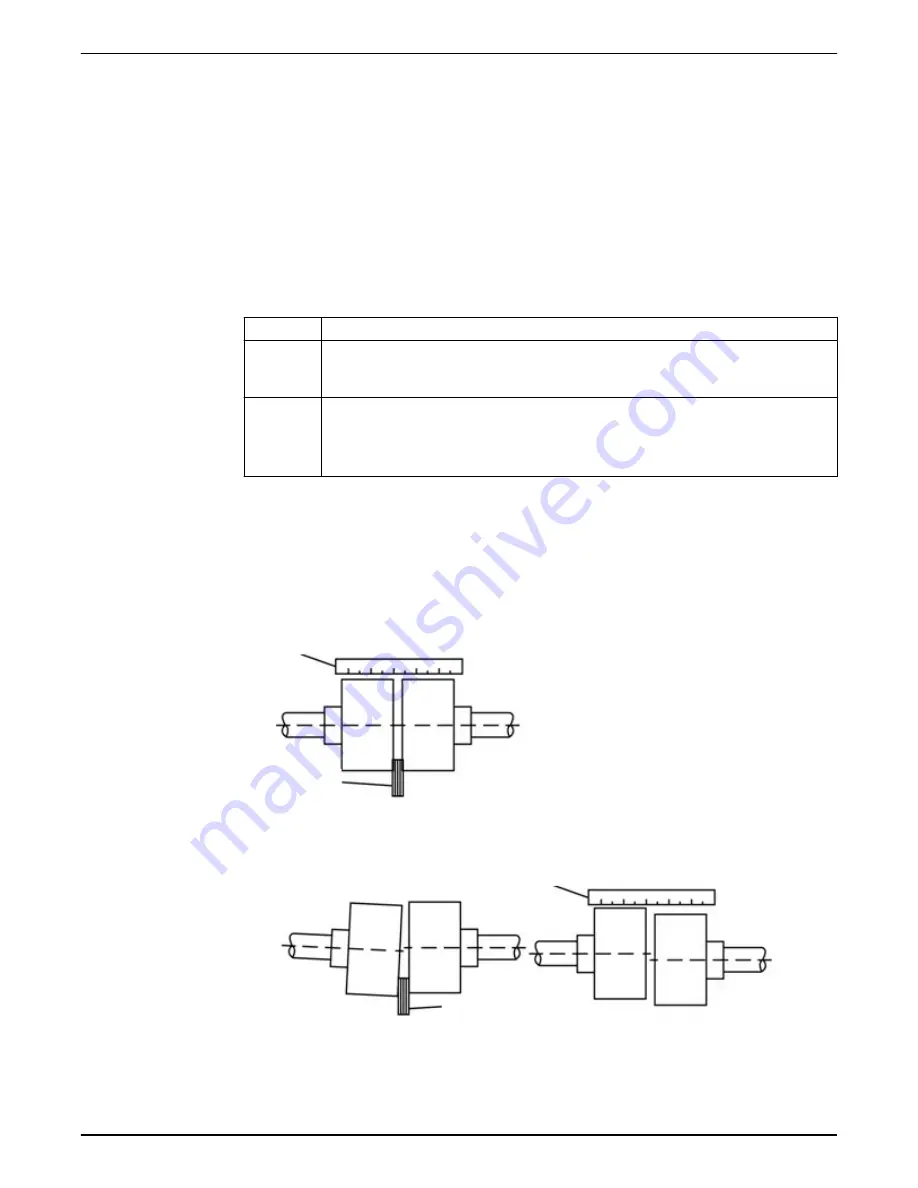

2. Check the parallel alignment:

a) Place a straight edge across the two coupler halves.

b) Measure the maximum offset at four points 90° apart. Do not rotate coupler.

c) Reposition the equipment until the gap is within the 1/64” permissible offset.

A coupling with a 3° angular misalignment will have a 0.191 in. (0.485 cm)

difference in measurements between L1 and L2. This is within the 0° to 4°

misalignment that is allowed for that size of coupling.

1

2

1. Straight edge

2. Feeler guage

Figure 4: Check the alignment using a straight edge - correct

1

2

Angular

Parallel

1. Straight edge

2. Feeler gauge

Figure 5: Check the alignment using a straight edge - incorrect

4 Installation

G&L Pumps Series A-C 8100 Base Mounted Centrifugal Pump INSTRUCTION MANUAL

17

Содержание G&L A-C 8100 Series

Страница 1: ...INSTRUCTION MANUAL AC5659D G L Pumps Series A C 8100 Base Mounted Centrifugal Pump...

Страница 2: ......