3

2

4

6

5

1

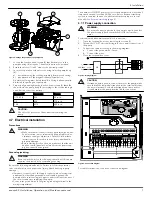

Figure 2: Change the position of the pump head

1.

Loosen the four hex-head screws (2) that fix the motor to the

pump housing (4) using the T-handle allen wrench described.

2.

Rotate the motor (1) in 90° steps to the desired position.

3.

In case of separation of the motor housing from the pump body

(4):

a)

avoid removing the rotating assembly from motor housing;

b)

pay attention to the magnetic hazard listed before.

A defective O-ring must be replaced. An O-ring is already availa-

ble inside the package as spare part.

4.

Properly align and tighten the four hex-head screws (2) that affix

the motor to the pump body (4) according to the torque table giv-

en below in a criss cross pattern.

Nominal HP

Screw size

Torque

1/12 & 1/6

M6

90 in-lb

1/2

M8

170 in-lb

1 & 2

M10

340 in-lb

CAUTION:

Check for the presence of leaks after reassembling the

pump.

4.7 Electrical installation

Precautions

WARNING:

• Make sure that all connections are performed by a quali-

fied electrician in accordance with all applicable codes,

ordinances and good practices. Failure to follow these

instructions could result in serious injury, death and/or

property damage.

• Before starting work on the unit, make sure that the unit

and the control panel are isolated from the power sup-

ply and cannot be energized.

Grounding (earthing)

WARNING:

Reduced risk of electric shock during operation of this pump

requires the provision of acceptable grounding.

Be sure the following are adhered to. Failure to follow these instruc-

tions could result in serious personal injury, death, and/or property

damage.

• If means of connection to the supply connection box (wiring com-

partment) is other than grounded metal conduit, ground the

pump back to service using a copper conductor at least the size of

the circuit conductors supplying the pump.

• Connect the ground wire to the green grounding terminal in the

wiring compartment.

The number of ON/OFF power cycles for the pump must be less than 3

times per hour and less than 20/24 hours. If more frequent start/stop

cycles are required, the use of a dedicated start/stop input is recom-

(page 9).

4.7.1 Power supply connection

WARNING:

Do not make any connection in the pump control box unless

the power supply has been switched off for at least 2 mi-

nutes.

For models with standard terminal block connection:

1.

Open the terminal box cover removing the screws (5).

2.

Thread the ½” NPT electrical fitting into the conduit connection of

the pump.

3.

Connect the cable according to the wiring diagram.

a.

Connect the ground wire, if used.

b.

Connect the wires.

4.

Close the terminal box cover.

1

2

3

L

N

115V

L

1

L

2

208-230V

CB

Figure 3: Wiring diagram

CAUTION:

If stranded wire is used to connect power to the pump, make

sure that all the individual strands enter the terminal block as

the wire is inserted. Peeled back strands can cause a short

circuit hazard at the pump terminal block connections.

Start /

Stop

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

C

N

L

NO 15V S+S- P+ P-

T+ T-

A

B

GND

A

B

GND

Figure 4: Connection diagram

For cable terminations, see above connection diagram.

4 Installation

ecocirc

®

XL Installation, Operation, and Maintenance manual

7

Содержание Bell & Gossett Ecocirc XL

Страница 1: ...Installation Operation and Maintenance manual ecocirc XL...

Страница 2: ......

Страница 17: ...Manual de instalaci n operaci n y mantenimiento ecocirc XL...

Страница 18: ......

Страница 35: ...Guide d installation d utilisation et d entretien ecocirc XL...

Страница 36: ......

Страница 51: ......