Note:

1.

The PLC can control 10 axes servo drives at the same time.

2.

PLC COM4 communication parameters keep default value. If it needs to change, please

use XINJEConfig software to set the parameters. The configureation method please refer

to appendix 1.

3.

The servo configuration method please refer to appendix 2.

4.

It cannot only cut the power of servo drive when the PLC and servo power on.

2-1-3. PLC software

XDC series PLC needs to use XDPpro software (v3.2.1a and higher version).

2-2. Instructions

Motion fieldbus instructions:

Instruction

Function

Soft component

Chapter

MOTO

Incremental position motion

MOTO pos spd acc axNs

6-2-1

MOTOA

Absolute position motion

MOTOA pos spd acc axNs

6-2-2

MOTOS

Multi-segment speed run

MOTOS data para axNs

6-2-3

MOSTOP

Stop running

MOSTOP para axNs

6-2-4

MOGOON

Continue running

MOGOON axNs

6-2-5

MOSYN

Synchronous run

MOSYN para syn_axNs axNs

6-2-6

MOUSYN

Release synchronous run

MOUSYN axNs

6-2-7

MOWRITE

Write the present position

MOWRITE data axNs

6-2-8

MOREAD

Read the present position

MOREAD data axNs

6-2-9

2-2-1. Incremental position motion [MOTO]

1. Instruction summarize

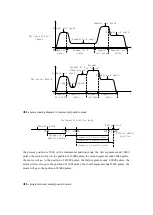

The instruction will run with incremental position, it can real-time change the target absolute

Содержание X-NET fieldbus

Страница 1: ...X NET fieldbus User manual Wuxi XINJE Electric Co Ltd Data No PD06 20151009 3 2...

Страница 28: ...SD169 Serial port 3 SD170 SD179 Serial port 4 SD180 SD189 Serial port 5 SD190 SD199...

Страница 56: ...d click the setting icon to open the setting panel Click write in PLC after setting...