09/2007

3-25

Phaser 8860/8860MFP Service Manual

IQ34, IQ35

Image Quality

Initial Issue

IQ34 Poor Ink Adhesion, Poor Image Durability

This RAP addresses image quality problems associated with the Print Engine. Poor ink adhe-

sion generally appears as a result of a overly glossy media coatings, or improper temperature

regulation of the Preheater or Drum.

Initial Actions

1.

Check that supported media is being used.

2.

Print an Information page from the Control Panel.

3.

Check the application print settings.

Procedure

IQ35 Massive Jet Loss

This RAP addresses image quality problems associated with the Print Engine. Significant jet

loss can occur during high-coverage printing due to ink starvation. Restricted ink flow typically

occurs in individual jets and is caused by air bubbles that form while the ink cools. These bub-

bles are usually cleared during the warm-up process or periodic cleaning cycles. More signifi-

cant ink flow restrictions can occur when the system is mishandled while the ink is in liquid

form. While ink is liquid, tipping, tilting, or using excessive force to close a tray can cause ink to

infiltrate the upper portions of the Printhead blocking the flow of ink and air.

Symptoms of mishandling include:

•

Ink in the Purge Hose

•

Ink reservoir overflow

•

Ink accumulations under the Printhead obstructing Printhead movement resulting in

7,010.43 errors.

•

Massive jet loss in one or more colors.

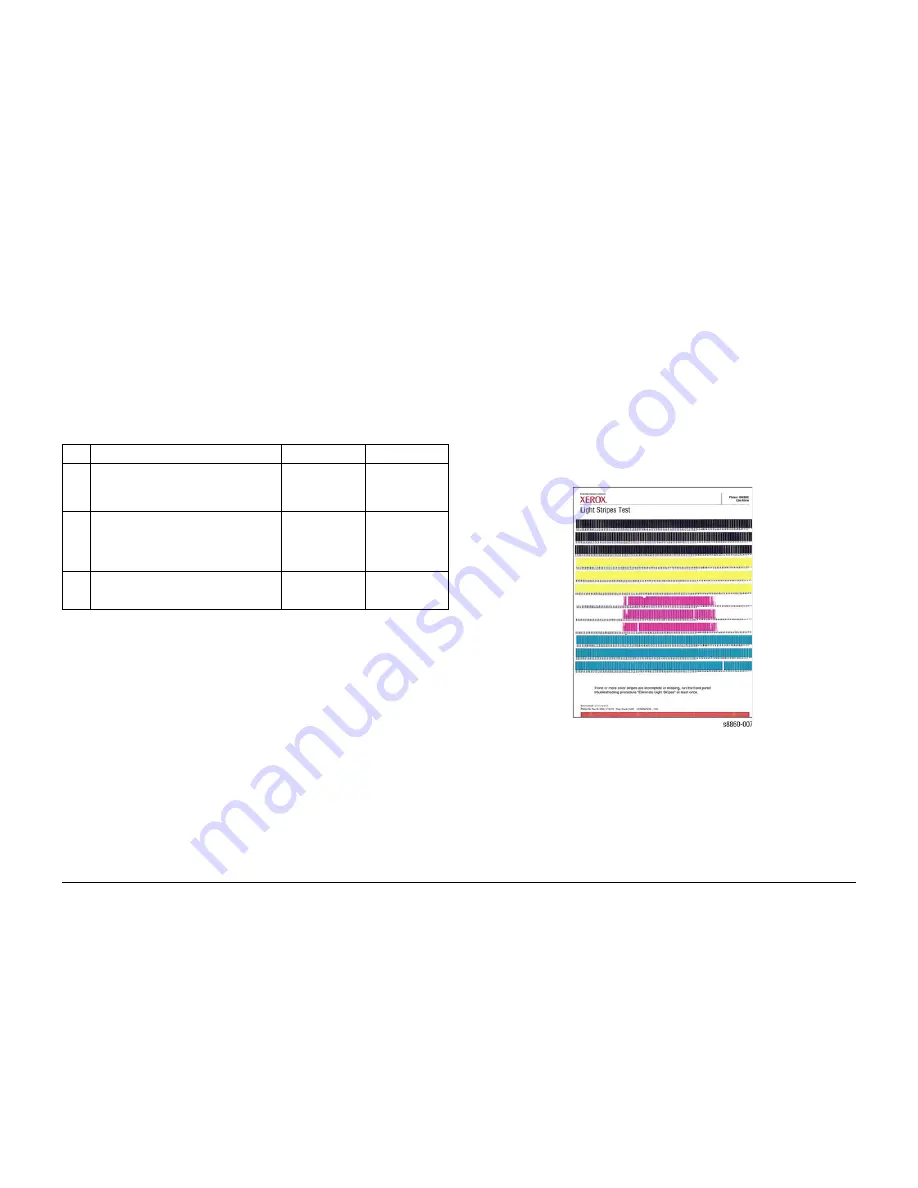

Figure 1

is an example of massive jet loss

Figure 1 Massive Jet Loss Example

Initial Actions

Inspect the Printhead for Ink overflow, blockage of the Purge Hose, or accumulations of ink

underneath the Printhead.

Procedure

If ink has been overflowing the Printhead reserviors, replace the Printhead.

Table 1 IQ34 Poor Ink Adhesion, Poor Image Durability

Step Questions and Actions

Yes

No

1

Check the media type and finish.

If the media appears glossy, replace the

media and reprint.

Does the problem persist?

Go to Step 2.

Complete.

2

Check the Preheater and Drum temperatures.

Run the Service Diagnostics Temperature

test.

Are the temperatures within specified ranges

(approximately 60 to 62 degrees Celsius)?

Go to Step 3.

Adjust the guides.

3

Check the position of the Drum Temperature

Sensor.

Is the sensor positioned properly?

Go to Step 4.

Correctly position

the sensor.

Содержание Phaser 8860

Страница 1: ...705P01205 September 2007 Phaser 8860 8860MFP Service Documentation...

Страница 4: ...09 2007 iv Phaser 8860 8860MFP Service Manual Initial Issue Introduction...

Страница 26: ...09 2007 xxvi Phaser 8860 8860MFP Service Manual System Specifications Initial Issue Introduction...

Страница 28: ...09 2007 1 2 Phaser 8860 8860MFP Service Manual Initial Issue Service Call Procedures...

Страница 34: ...09 2007 2 2 Phaser 8860 8860MFP Service Manual Initial Issue Error Messages and Codes...

Страница 92: ...09 2007 2 60 Phaser 8860 8860MFP Service Manual Jam Codes Initial Issue Error Messages and Codes...

Страница 94: ...09 2007 3 2 Phaser 8860 8860MFP Service Manual Initial Issue Image Quality...

Страница 126: ...09 2007 4 2 Phaser 8860 8860MFP Service Manual Initial Issue Repairs and Adjustments...

Страница 208: ...09 2007 5 2 Phaser 8860 8860MFP Service Manual Initial Issue Parts List...

Страница 222: ...09 2007 6 2 Phaser 8860 8860MFP Service Manual Initial Issue Diagnostics...

Страница 272: ...09 2007 6 52 Phaser 8860 8860MFP Service Manual Printhead Troubleshooting Checklist Printhead Initial Issue Diagnostics...

Страница 274: ...09 2007 7 2 Phaser 8860 8860MFP Service Manual Initial Issue Wiring Data...

Страница 294: ...09 2007 8 2 Phaser 8860 8860MFP Service Manual Initial Issue Theory of Operation...