16

[WorkInG as DIrect current WeLDer]

In this function, the selector (1) must indicate the current range indicated on the packing of electrodes

that will be welded. Welding cables (3) et (4) must be connected to the correct polarity also depending

from the instructions on the electrode packing. At last, using main welding current selector (2) it is pos-

sible to set the most suitable current to weld the used electrode.

IMportant

every time the machine is used as welder it is necessary to disconnect the load from the sockets of the

alternator to avoid any damage that can be caused by voltage fluctuations while the machine is welding.

The welder can supply the maximum current in output during a limited time after a necessary cooling

time (see the information on the plate). If during the work, with some high current the thermal breaker

is “on”, you have to wait few minutes before resetting it.

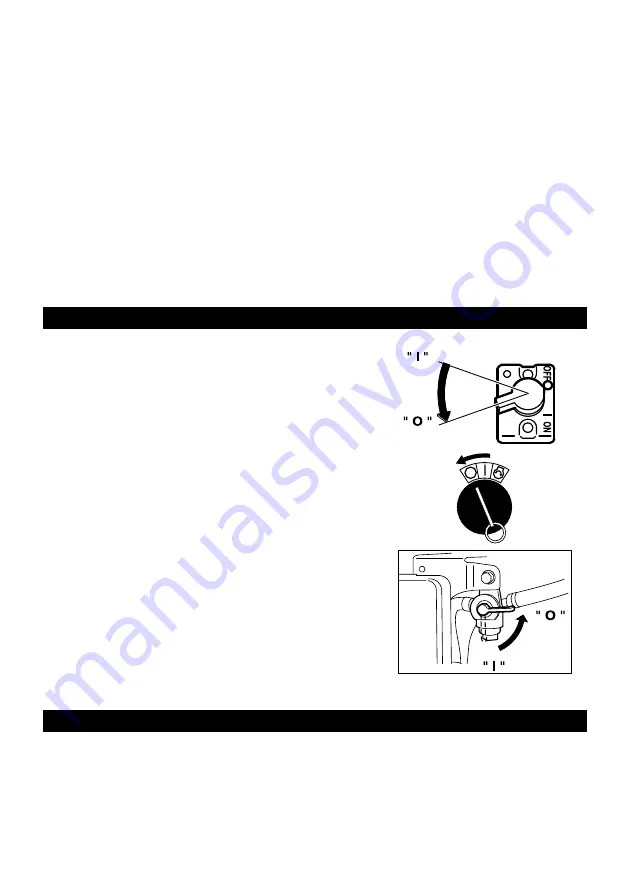

6. stoppInG the Generator

1. Turn off the power switch of the electric equipment and

unplug the cord from the receptacle of the generator.

2. Allow the engine about 3 minutes to cool down at no-load

before stopping.

3. Turn the engine switch to the position ‘‘

o

’’ (OFF).

4. Close the fuel cock.

7. oIL sensor

•

The oil sensor detects the fall in oil level in the crankcase and automatically stops the engine when

the oil level falls below a predetermined level.

•

When engine has stopped automatically, switch off generator’s no-fuse breaker, and check the oil

level. Refill engine oil to the upper level as instructed on page 8 and restart the engine.

•

If the engine does not start by usual, consult your nearest Robin dealer or service shop.