29

3062880_0910

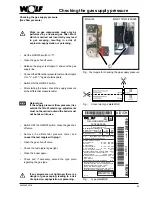

Changing the gas type / CO

2

settings

D) Completing the adjustments

• Shut down the boiler and close the test ports and hose

nipples; check for tightness.

C) Checking the CO

2

setting

• After completing the work, refit the casing cover and

check the CO

2

value with the appliance closed.

Observe the CO emissions whilst making

CO

2

adjustments.

The gas combination valve is incorrectly

adjusted, if the CO value is >200 ppm, when

the CO

2

value is correct.

Take the following steps:

Check the standard settings of the zero point and

throughput adjusting screws at the GCV and restrictor.

• Repeat the adjusting process from section A.

• The condensing boiler is correctly adjusted when the

CO

2

values correspond to those in the table below.

Appliance closed

(without casing) at

upper

load

Natural gas H

9.3% ± 0.3%

Appliance closed

(with casing) at

lower

load

Natural gas H

9.1% ± 0.3%

Fig.: Gas combination valve

MGK-170/210/250/300

MGK-130

Zero point adjusting screw, Tx40 Torx (under the

cover)

Gas throughput adjusting screw (under cover)

Allen screw 3 mm for the MGK-170 - MGK-300)

Slotted screw for the MGK-130